Owner: Etergo | Publication date: 2021

Field of expertise:

Methods:

Application area:

Industry:

Etergo is a developer and manufacturer of novel, lightweight, rapid-acceleration electric vehicles. This case study outlines how the strong integration between our flagship Ansys Workbench solvers used with Ansys Granta Selector can help engineers make the right materials decisions for their designs faster with reduced simulation and testing costs.

Challenges

When faced with developing a new model of their electric scooter, Etergo turned to Ansys to help solve their development challenges. New materials had to be compared to minimize cost and weight to meet exacting specifications. With strong demand for their product, rapidly getting to market with their new generation scooter is a key driver.

Technology used

- Ansys Granta Selector + Advanced Materials

- Ansys Workbench

Engineering solution

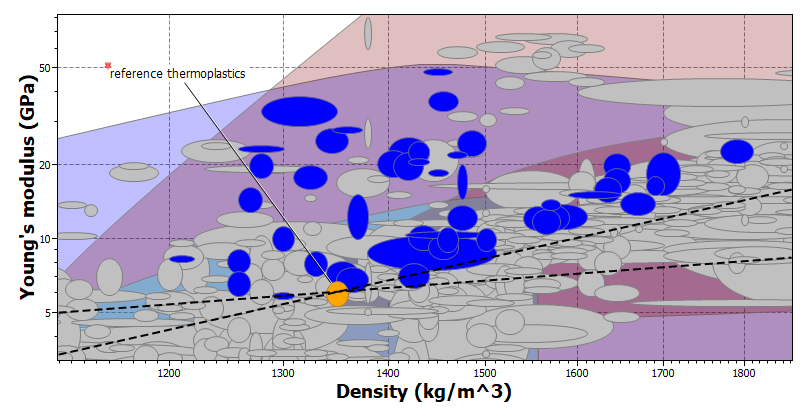

Leveraged Ansys Granta Selector for materials selection, analysis and data together with Ansys Workbench to simulate new material performance. Advanced materials data: Metals. Gateway between Ansys Granta Selector and Workbench for automatic material data transfer.

Benefits

Reduction in unnecessary simulation and testing costs by eliminating unqualified materials early in the design. Material use optimization with cost and weight reduced. Workbench simulation results using Selector materials – data corresponds well to experimental testing. – The powerful interface between Ansys Workbench and Selector saves time with quick, accurate data transfer.

“By using Granta Selector, we can find a material that satisfies all ten material constraints for this application. We can down select from 4,000 options down to 20 best candidates. Then we can rank them by price. Granta Selector is not only a materials selection tool. It can also interface with Ansys Workbench. As a finite element analyst, I’m going to do finite element simulations every day so the interactions between these two packages and the reliability of the data is of great interest to me.” says Long Wu, Finite Element Analyst at Etergo.

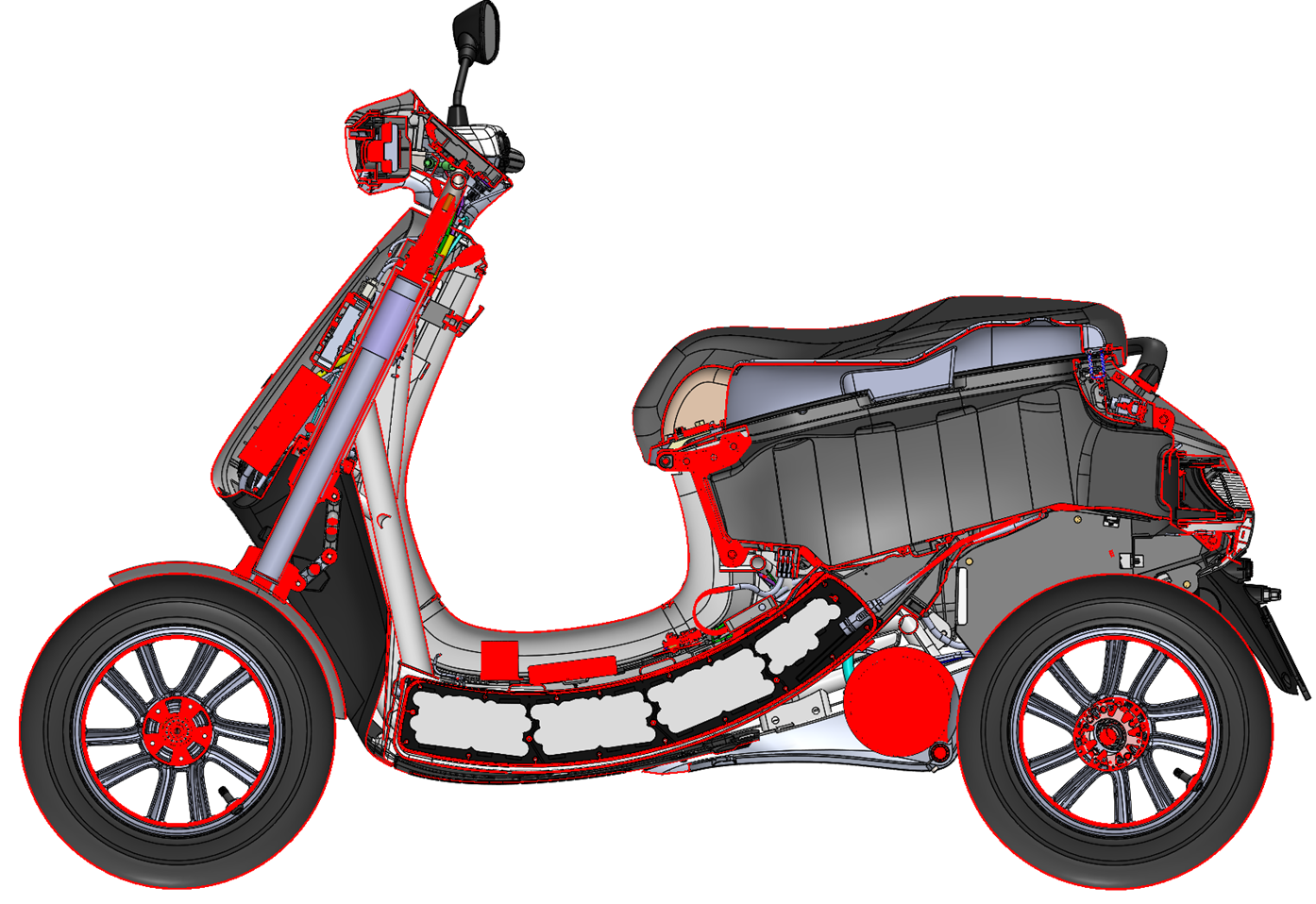

Etergo’s electric scooters

Half section view of the scooter model

Material selection with Granta