Owner: KEPCO KEPRI

Field of expertise:

Methods:

Application area:

Industry:

KEPCO KEPRI is developing power plant operation platforms and an AI-based application for predictive diagnostics for different power generation fields, such as combustion. KEPCO helps to digitalize power generation sector. The platform developed by KEPRI combines big data platform with cloud platform. This enables it to connect to various systems and rapidly process data.

Challenges

Coal-fired power plants nowadays require frequent operational adjustments regarding design parameters like quick input changes and long periods of low load operation. Because of this, boilers in such power plants need appropriate adjustments of operating variables to balance out the localized temperature caused by output changes and low load operations, which lead to a higher chance of slagging and fouling, and nitrous oxide within the furnace. Such events cause lower efficiency of the power plant, as well as change in environmental facilities needed for it.

Adjustments of operating variables which would fight these issues through traditional CFD analysis could take weeks. Due to this, a technology using reduced order models which could analyse the phenomena within seconds is required. KEPRI used Ansys Fluent, Ansys HPC and Ansys Twin Builder to predict the imbalance of the boiler combustion temperature and environmental pollutant contents within the gas. This made it possible to easily assess the effect following the configuration of operating variables.

Technologies used

- Ansys Fluent

- Ansys Twin Builder

- Ansys HPC

Engineering solution

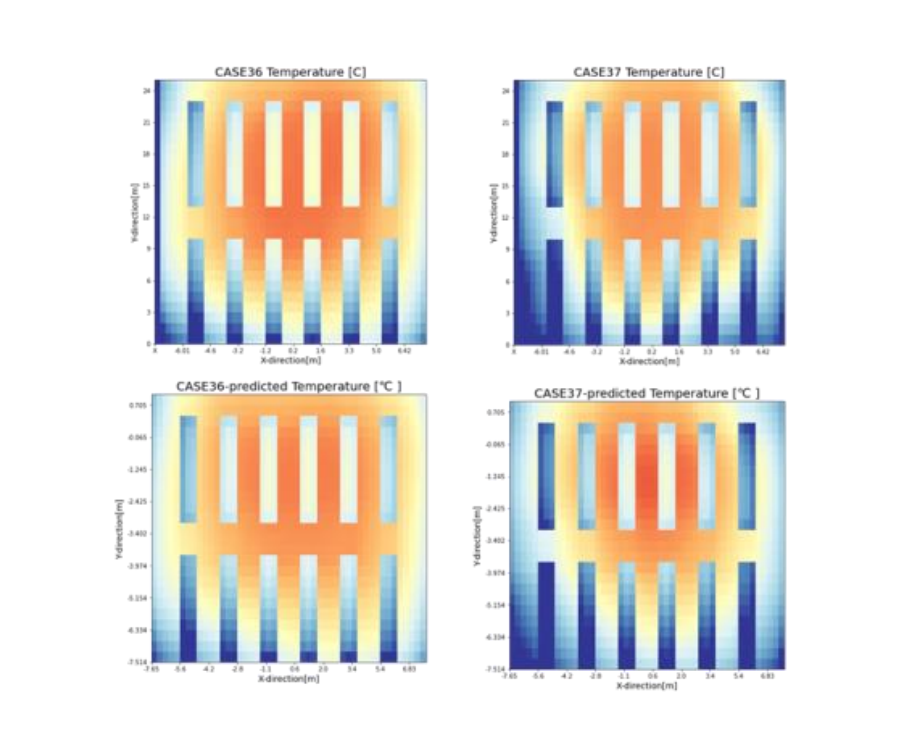

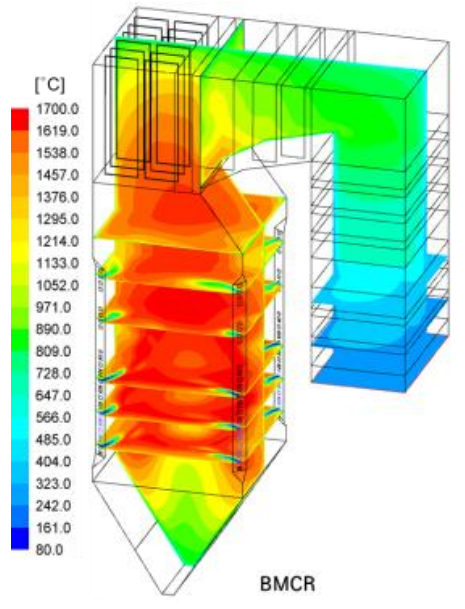

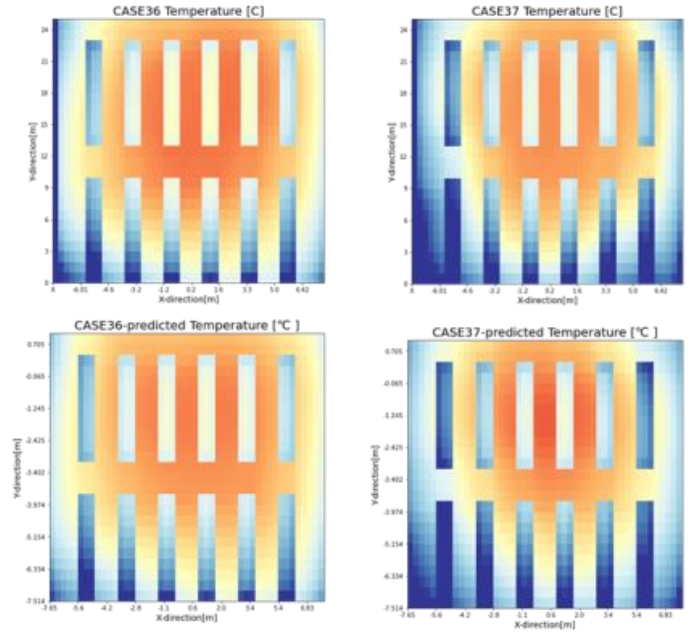

Ansys Fluent was used for developing an appropriate CFD model of a boiler. Four critical variables affecting the outlet temperature distribution were selected. A number of CFD simulations was conducted using Ansys HPC with Latin Hypercube Sampling. Engineers developed a reduced order model for the chosen variables. As a result of the analysis they obtained a predictive value with 96% similarity within only 3 seconds. Using Ansys Twin Builder, they could predict gas temperature distribution at outlet and change of nitrous oxide and sulfur oxide over time. Compared to measurements, the predictions were within 92% accuracy. KEPRI developed a simulator which can predict the 2D outlet temperature distribution of coil-fired boiler and average properties of gas, and predict the effects of operating variables configuration. This would lead to increased efficiency of the boiler and less pollutants in the gas.

Benefits

The simulator which KEPRI developed using Ansys products enables operators to take countermeasures against errors within the furnace in real time. They expect this to increase boiler efficiency, namely boiler heat rate by at least 0.5%, and decrease environmental pollutants by at least 10%.

Coal Firing Power Plant

Boiler Coal Combustion CFD Simulation

Comparison of Analysis Data and Predicted Data