Owner: Titan Subsea Innovations | Publication date: 2022

Field of expertise:

Methods:

Application area:

Industry:

Titan Subsea Innovations, LLC is a Houston-based subsea pipeline connector company that provides unique, engineered solutions for new construction, repairs, tie-ins, abandonments and reroutes. In conjunction with engineered solutions, Titan Subsea Innovations provides offshore technical support for product installations. Titan offers quick turnaround deliveries to clients using stock components that are essential for performing emergency pipeline repairs. The seasoned professionals at Titan Subsea Innovations have extensive experience and share that expertise with clients worldwide.

Business challenges

The Titan Misalignment Flange (TMF) provides multiplanar, angular adjustment during pipeline makeup. Once the TMF is set, it must provide a permanent metal-to-metal seal in a fixed geometrical position. In this condition, the TMF is then essentially a pressure vessel with a complex geometry that cannot be perfectly represented by closed-form solutions. Titan was awarded an order for a TMF with a 10,000 psi pressure rating. It needed a solution to ensure both the sealing and structural integrity of the product.

Technology used

Engineering solution

Titan Subsea Innovations used Ansys Mechanical structural software to run FEA simulations on its imported 3D CAD models. The automatic contact detection feature, simplified meshing tools and intuitive graphical user interface enabled an easy setup of the simulation. Post-processing tools, such as stress path linearization and contact pressure mapping, delivered a simple and reliable assessment of how well the flange complied with applicable specifications and design criteria. When engineers modified a CAD model based on results, the simulation setup updated smoothly while maintaining all the parameters of the previous iteration.

Benefits

The Ansys FEA simulations allow for efficient design and validation of Titan’s products. When the TMF was assembled and tested, it performed perfectly as predicted by simulation. Not only do Ansys simulations save the hundreds of engineering hours required for manual design verification, they also produce outputs that give our clients a greater sense of confidence in our product designs.

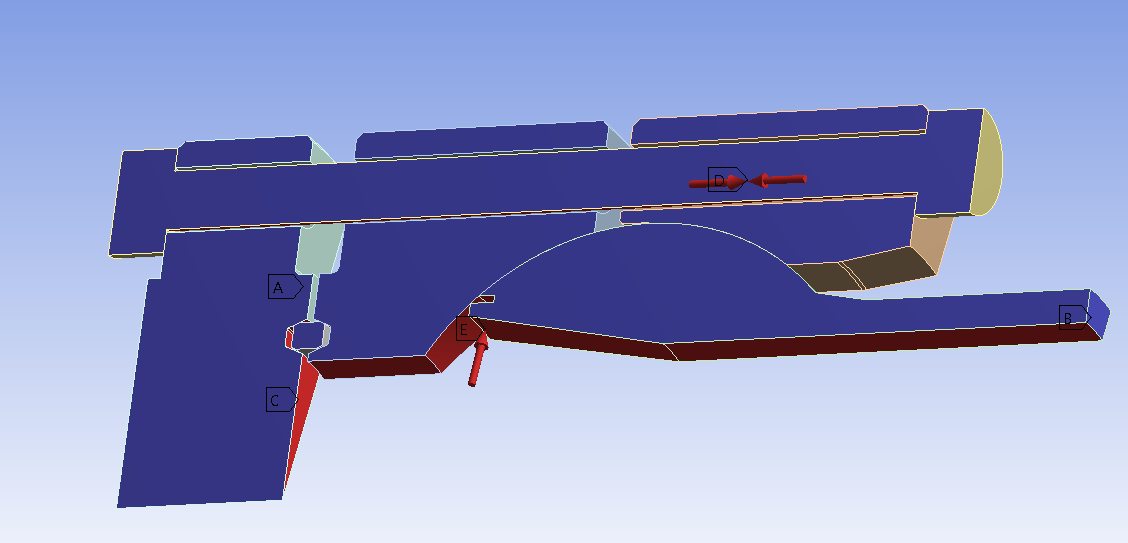

Applied loads and boundary conditions

on partial section model

of the Titan Misalignment Flange

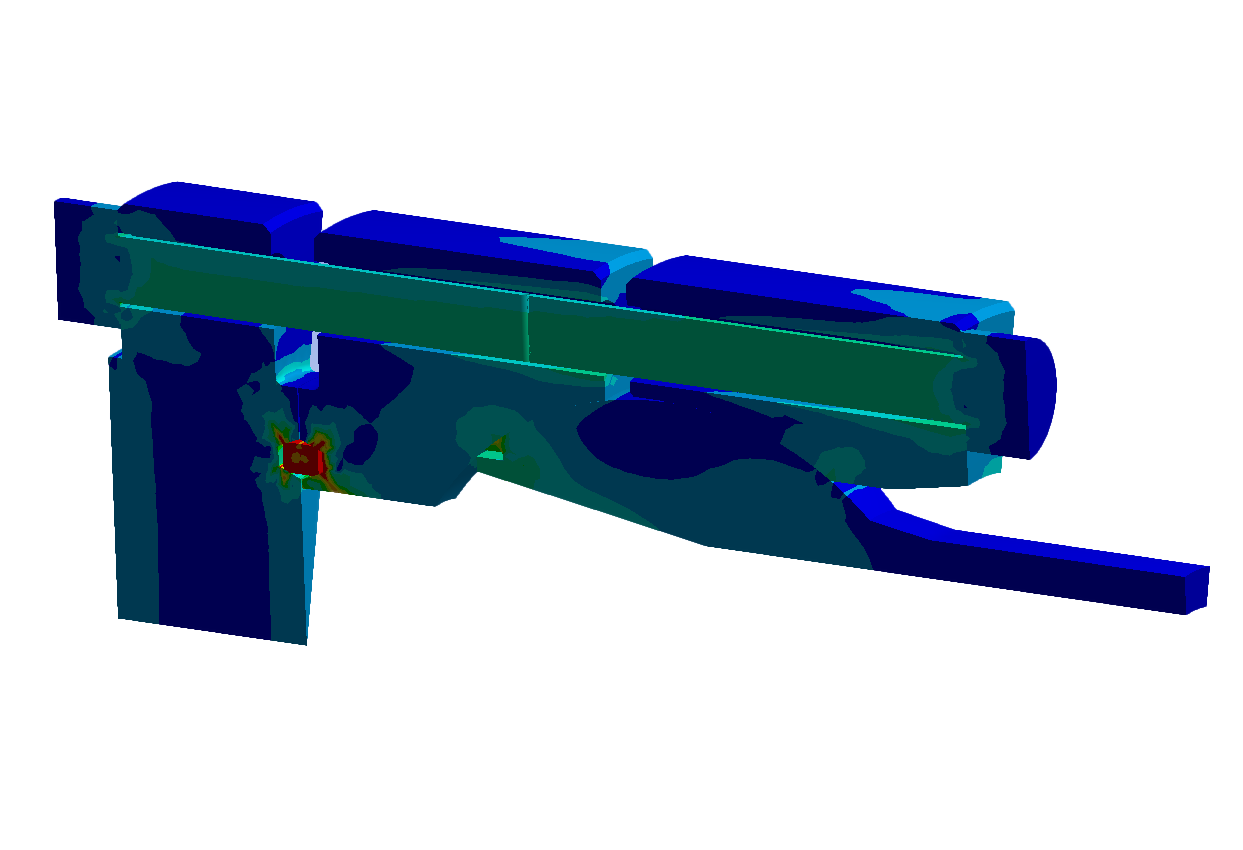

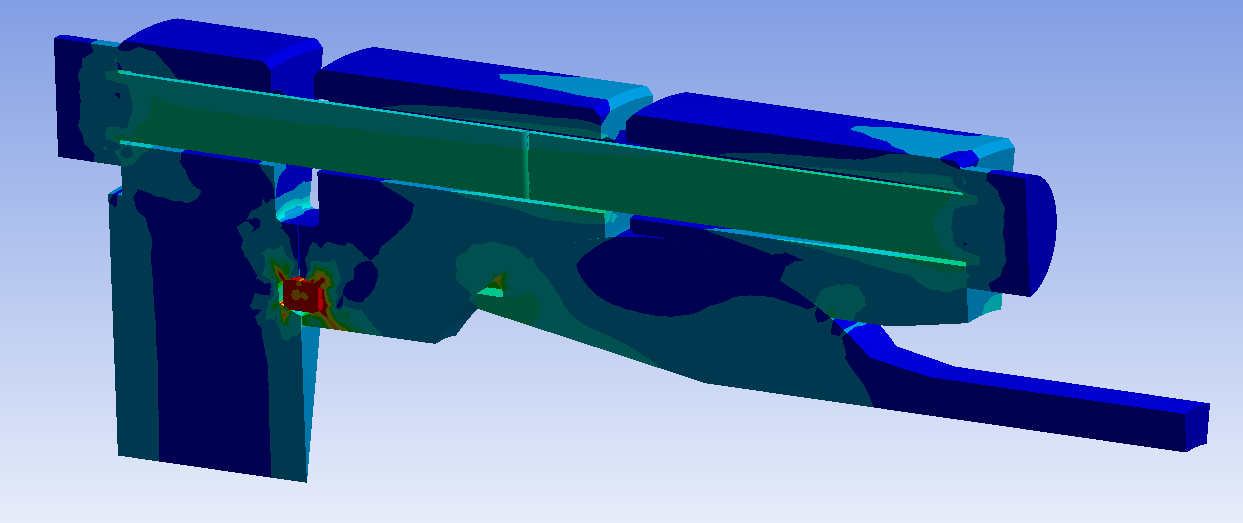

Equivalent von Mises stress

of Titan Misalignment Flange