Owner: Vitesco Technologies

Field of expertise:

Methods:

Application area:

Industry:

Vitesco Technologies integrates powertrain system solutions for all kinds of vehicles. With scalability and modularity, they fulfil the requirements for cars, commercial vehicles, two-wheels transport and new mobility concepts. Their Sensing & Actuation Business Unit designs key elements of automated systems, such as door handle sensors which detect when a user touches the handle to lock or unlock the vehicle.

Challenges

For automakers, light is a very important part. Not only for practicality and comfort, but also to differentiate vehicle brands and make them recognizable. One of the ways to do this is integrating lighting systems into vehicles’ door handles. Developing an optical system that meets customer specifications, integrates electronic sensors and satisfies international regulatory standards can be complex. Design of the door and handle needs consideration together with multiple physical parameters such as mechanical, electronic or optical. Iterative validation process of physical testing can be very expensive. The reason is that it requires validation under final conditions, which makes the prototypes expensive.

A lot of preparatory work is also necessary for the validation since the tests need to consider many criteria such as weather conditions, visibility or brightness. Because of this, a tool for studying and testing multiple concepts, while reducing prototyping to minimum is needed.

Technologies used

Engineering solution

Ansys SPEOS enabled the engineering team to model and validate all optical systems of the door handles to guarantee lighting results which comply with specifications. Models of different components such as handle or lightguide can be implemented and simulated in their final environment. This makes it possible to analyse interactions between light and materials in real use conditions and lightings. Many hypothetical scenarios can be explored and results can be visualised in a realistic way. This enables the engineers to control the full product design process in real time, from development of the concept, to validation and preparation for mold manufacturing.

Benefits

Since they started using SPEOS, Vitesco has significantly reduced time and cost of lighting systems’ design and validation, which lead to accelerated time to market. During less than 15 years of SPEOS usage, development time has reduced by 75%. Number of physical prototypes needed for validation has been drastically reduced.

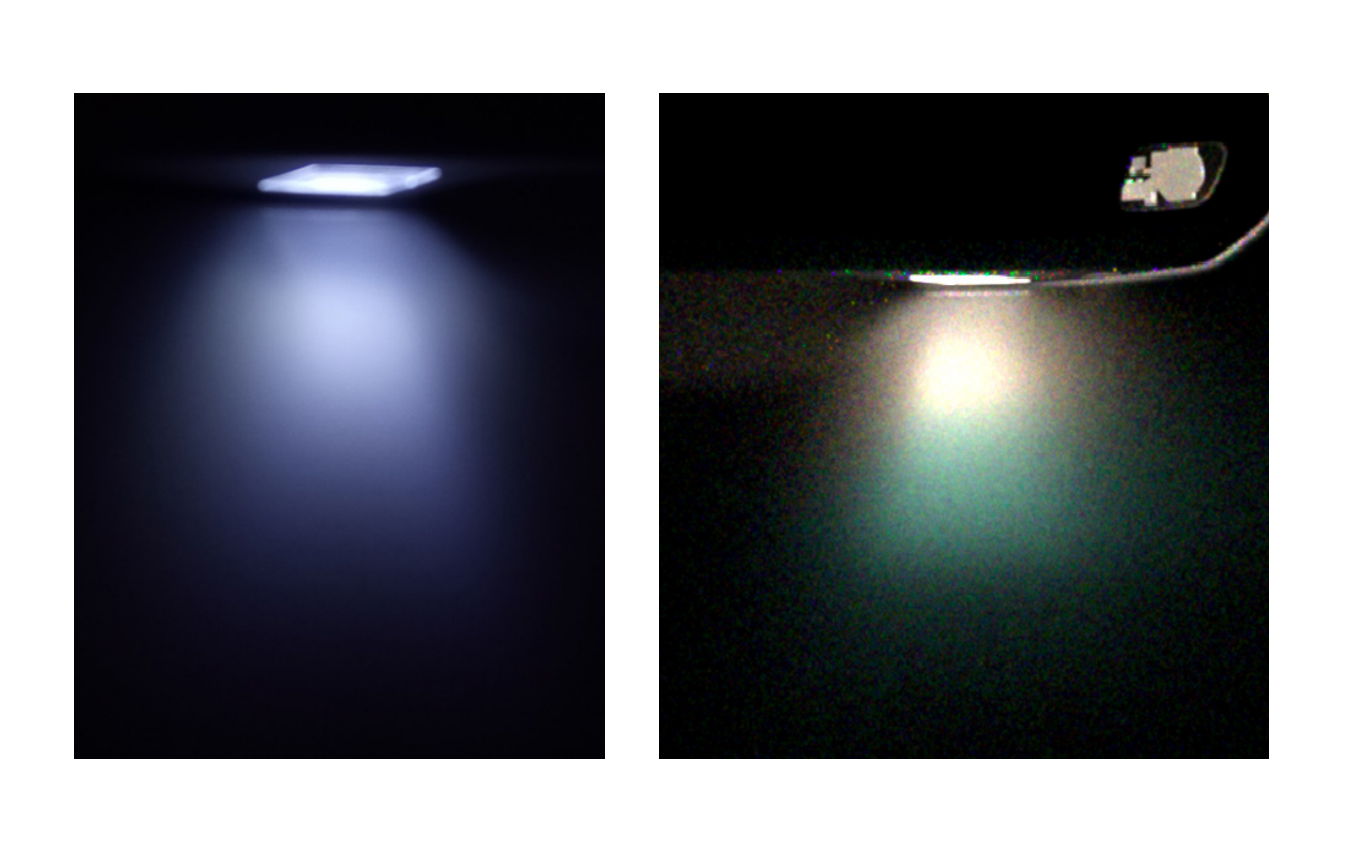

Comparison between a photograph (left)

and simulation (right) of the global lighting.

The simulated system has the undesirable

parasitic effect which is present

on the real system

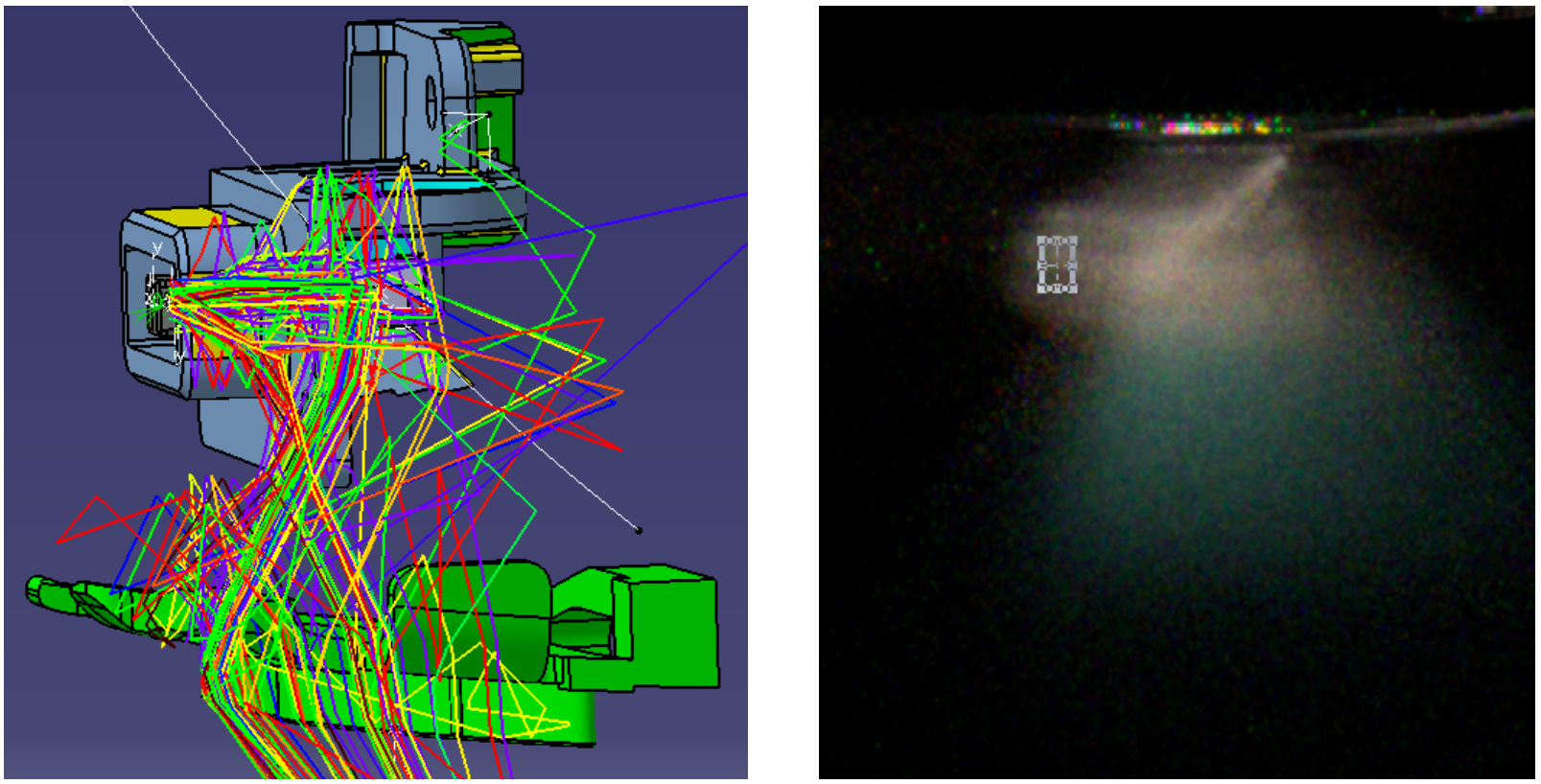

Parasitic effect origin identification with SPEOS