Field of expertise:

Methods:

Application area:

Industry:

Rheinmetall as a global acting technology group in the segment security and mobility is confronted with the industry’s well-known constant pressure from customers to further increase performance as well as quality while simultaneously raising development efficiency. This challenges the development process, and to fulfil both demands, extensive use of simulation is required to support decision-making. In particular, there is a need for simulation-driven design exploration and optimization. To realize the targeted design improvements a profound product understanding is the base to successfully optimize design performance, quality and costs.

Challenges

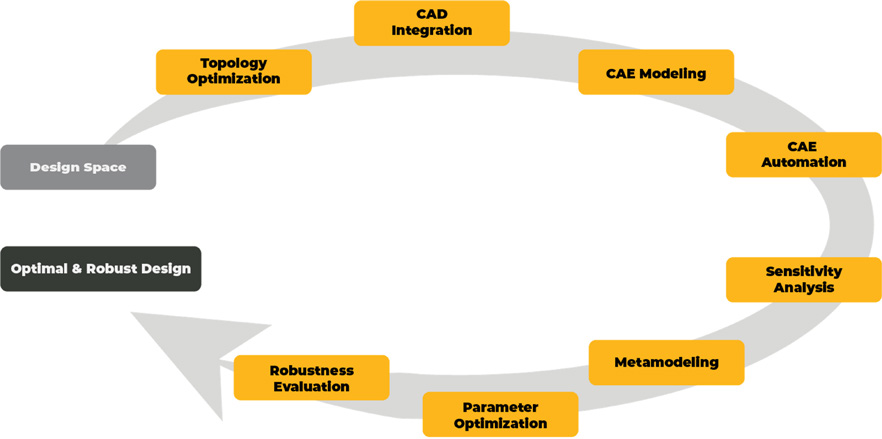

Central simulation department of Rheinmetall’s mobility area supports all Division’s Business Units as the internal CAE service supplier, executing a broad spectrum of CAE tasks to support the development teams expanding and improving company’s extensive product portfolio, which ranges from parts for internal combustion engines to parts for hybrid and electrical vehicles. Needing to streamline design optimization throughout their processes and develop optimal and robust designs, the team uses optiSLang to perform sensitivity analysis, surrogate modelling, parameter optimization and robustness evaluation.

Technology used

They used Ansys optiSlang, Ansys Workbench and Ansys Electronics Desktop.

Engineering solution

Inspired by the idea of simulation driven design optimization, Rheinmetall performs CAE variants analysis in various development projects. optiSLang supports setup and execution of customized CAE workflows on the one hand side. It provides required analysis tools and algorithms on the other side to create following results:

- Obtaining a system-based understanding of designs under variability as fundament for efficient part development.

- Disclosing optimization potential and determining operating limits.

- Receiving optimized and robust designs.

Convinced by optiSLang technology, Central simulation department of Rheinmetall deployed collaborative efforts to introduce optiSLang across the company. They expanded the software’s usage from pilot projects to broad usage in multiple CAE disciplines over the last six years. Next, Rheinmetall will expand optiSLang’s international usage, and launch an innovative service platform to internal customers thanks to optiSLang web-service.

Benefits

Simulation-driven design optimization simultaneously reduces development cost and time. It also optimizes design performance according to requirements, using all available design freedom. Early design studies, which are an indispensable part of simulation-driven design optimization, provide the development team with frontloading advantages and deliver a complete view on feasibility, risks and costs. This significantly reduces the number of required prototypes.

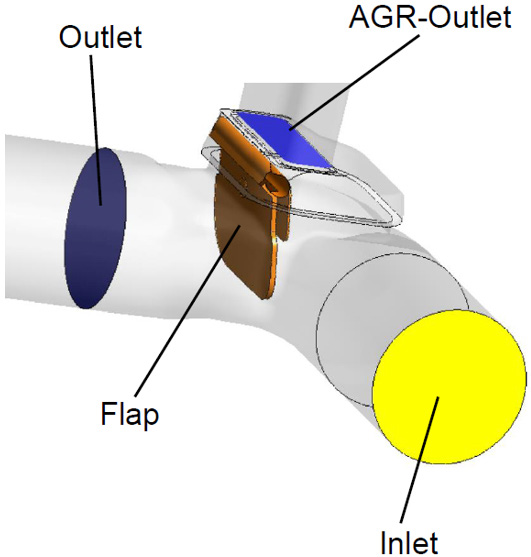

EGR flow chamber – flap valve

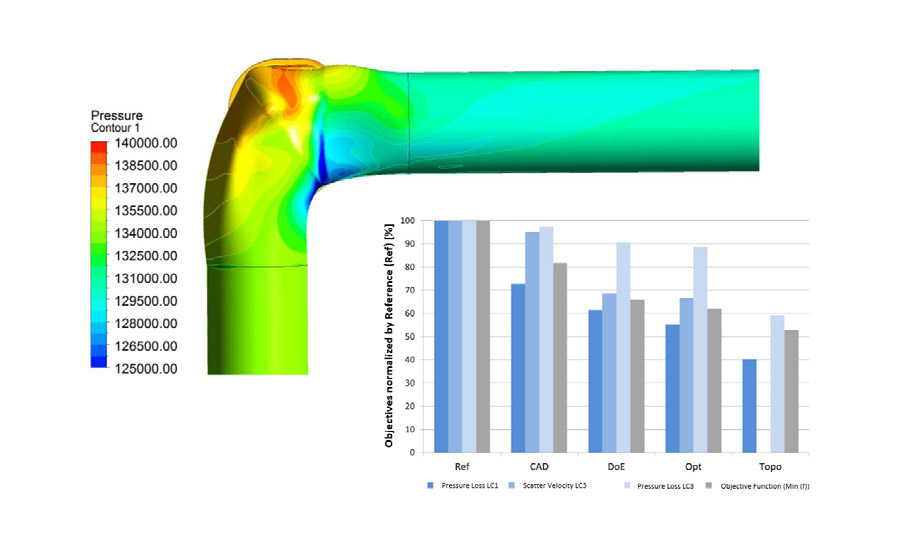

Results of continuous optimization workflow application

on EGR flap valve flow volume

Continuous workflow from topology optimization

to robustness evaluation