Owner: watttron | Publication date: 2022

Field of expertise:

Methods:

Application area:

Industry:

About the company

The watttron company is a spin-off from the University of Technology, Dresden, and Fraunhofer IVV Dresden, founded in 2016. The goal of wattron company is to revolutionize packaging and many other industrial processes. Their new, innovative heating system in thermoforming provides numerous advantages. Most importantly, they improve control and flexibility of the process, as well as increase efficiency and product quality.

Challenges

The core of watttron’s technology are modular designed matrix heaters. Such heaters consist of a number of small resistance heating circuits in the form of square pixels printed on thin, isolated ceramic substrates. They enable generation of temperature profiles specifically adapted to given products or molds. However, optimal temperature needs to be determined for each of these pixels and manual calculation of these temperatures would be extremely time consuming.

Technologies used

- Ansys SpaceClaim Design Modeler

- Ansys Mechanical

- Ansys Polyflow

Engineering solution

By using Ansys, watttron developed a powerful algorithm which iteratively updates temperature profile depending on the results of thermoforming simulation. The first step of the optimization process is thermoforming process simulation and an initial temperature profile. With this data, initial wall thickness distribution is obtained. Then the algorithm uses the obtained data to update the temperature profile and start the simulation of thermoforming process for the second time. This is repeated until the wall thickness is almost constant at every location of the product.

Benefits

Using Ansys simulation software resulted in decreased time and cost needed to determine the process parameters. Furthermore, this enabled watttron to provide feedback to the customers faster and allowed them fast return in investment.

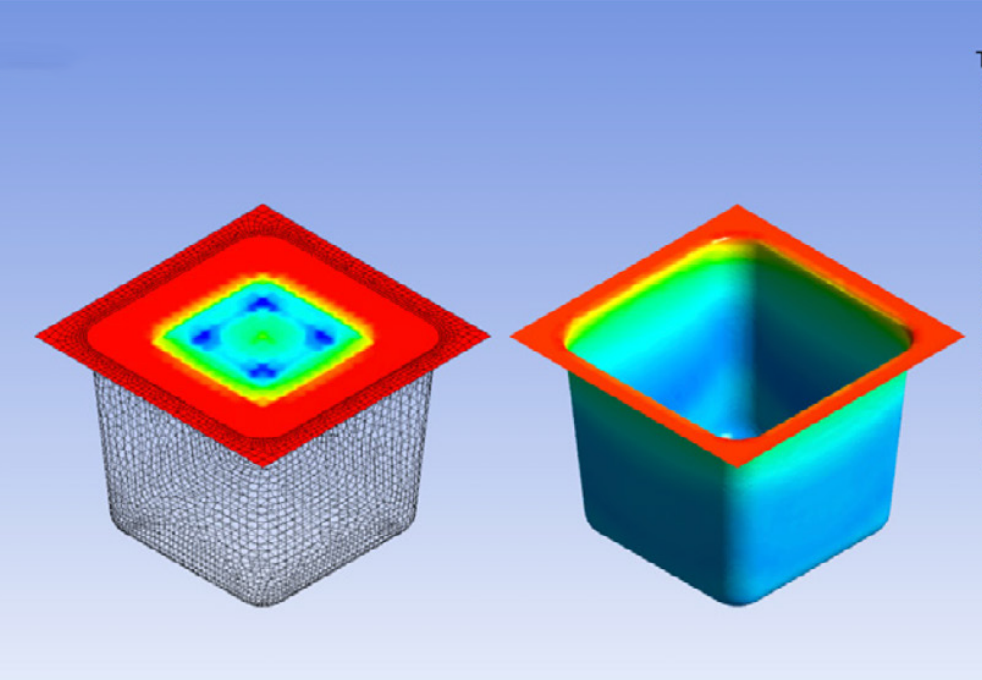

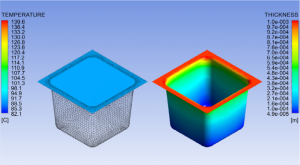

Homogenous temperature profile (left)

and resulting wall thickness distribution (right)

for a simple test cup

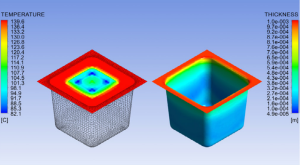

Optimized temperature profile (left)

and resulting wall thickness distribution (right)

for a simple test cup