Owner: Kylie Battles | Publication date: 24 June 2022

Field of expertise:

Methods:

Application area:

Industry:

About the company

Revindus develops and manufactures multi-discipline engineering products with state-of-art tools. The biggest advantage of Revindus is combining their knowledge with new technologies. They are focused on measuring compressed gas flow precisely with a sonic nozzle. Unlike traditional designers, expert engineers at Revindus continuously invest in high tech designing tool knowledge in order to achieve the best results in the market.

Challenges

Liquid-gas separators are widely used in various industries. The most common type for gas and compressed air compressors is an oil-flooded screw compressor. Separator tank size affects dimensions of the package. Hence, it is crucial that the compressor has a robust and compact size. For such compressors, a common type of design is cyclonic. In order to achieve size reduction and separation enhancement, an inlet device was supposed to be used. Since a number of parameters needed to be handled, engineerins used a simulation tool to make the process easier.

Technologies used

- Ansys Space Claim Design Modeler

- Ansys Meshing

- Ansys Fluent

- Ansys Results (CFD-Post)

Engineering solution

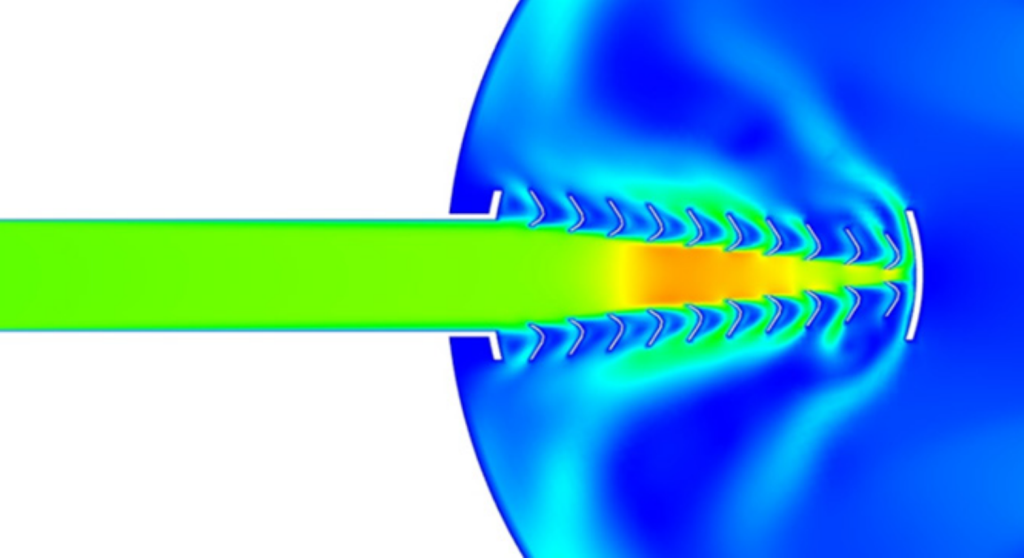

When analysing the inlet device of the liquid-gas separator the experts used Ansys Fluent Transient VOF solver to simulate single phase and multiphase flow with relevant interactions, with gravity enabled. Firstly, they carried out a parametric study, with purpose of optimizing length to diameter ration of the tank, to enhance gravitational separation performance. Furthermore, they tunded number, angle and distance of the guide vanes to achieve the best velocity distribution. Lastly, they used transient multiphase solver (VOF) with implicit body force and enabled gravity in order to analyse separation performance.

Benefits

It was proven that Ansys Fluent is a very powerful engineering tool for CFD calculations. If engineers took a trial-and-error approach instead, the project described above would have been extremely time consuming and expensive, without providing the team with deep understanding of the design. Thanks to Ansys Fluent, they achieved significant savings in manufacturing and testing hours since a numerous amount of variation did not have to be considered for that. Evenutally, they optimized two main liquid-gas separator types with nine combinations each. Without Ansys, the company would not have been able to invest, manufacture, test and recalibrate all of those combinations.

Velocity contour of the optimized inlet device

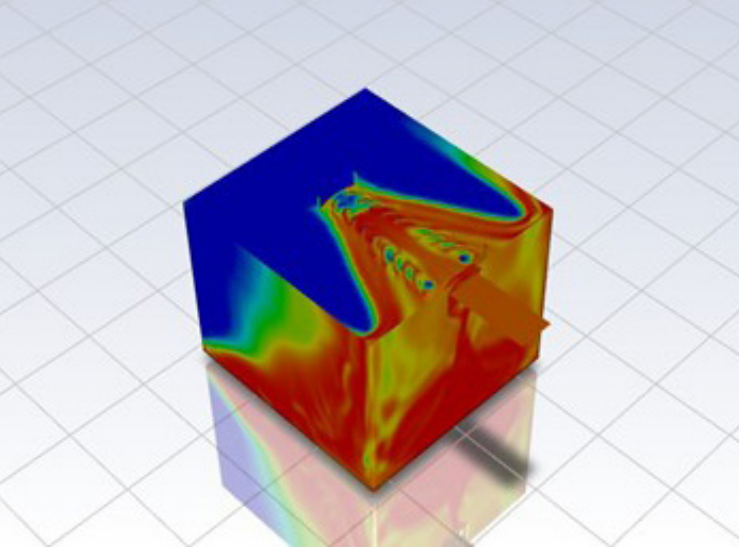

3D separation of oil (cut in view)

A captured image during separation of liquid phase

with inlet device guiding effect