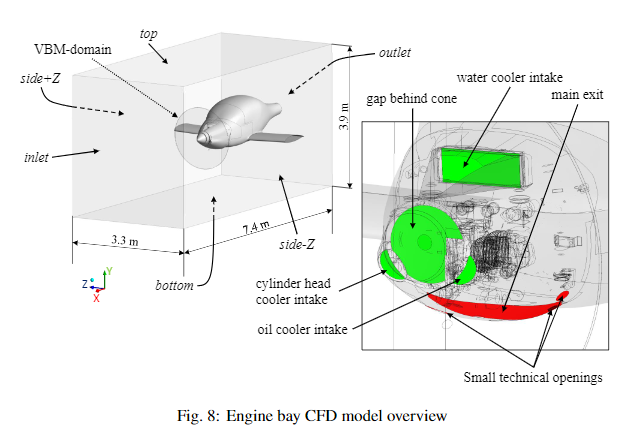

Computational Fluid Dynamics solutions offer comprehensive tools for simulating fluid flow, heat transfer, and fluid-structure interactions. Key products include Fluent, CFX, and ParticleWorks, each designed to address specific industry needs from aerodynamics to turbomachinery. CFD is essential for optimizing performance, reducing physical testing costs, and accelerating innovation. Its applications range from aerospace and automotive to energy and electronics, enabling precise analysis of complex scenarios. CFD aims to empower engineers to predict fluid behavior with remarkable accuracy, allowing for improved designs and innovation. Benefits include enhanced efficiency, better product performance, and reduced time-to-market. Our CFD software overcomes challenges such as high computational demands and complex simulation setups with user-friendly interfaces, robust solver technologies, and comprehensive support, ensuring engineers can confidently tackle intricate fluid dynamics problems and drive success.

- Single window workflow

- Streamlined Turbomachinery setups

- Multi-stage CFD modeling

- Harmonic blade methods

- Chemical reaction path analysis

- Fast chemistry solver for combustion engines

- Market leading animation software

- Ice cracking and shedding for rotating systems

- Library of validated fuel-combustion mechanisms

- Simulate rheological material manufacturing

- Create conformal mesh for blades

- Aerodynamic and hydrodynamic blade designs

- Model 3D rotating machinery

- Multi-GPU solver

- Realistic particle shape simulation

- Optimize turbomachinery design

- Simulate liquid behavior

- Multiphysics fluid-structure interactions

Capabilities

CFD products give you the power to make incredible progress through innovation. With the industry's most accurate and trusted solvers, you can be confident in your results. Whether you want to maximize the efficiency of an internal combustion engine or simulate in-flight icing, we have the tool for you.

Explore our capabilities!

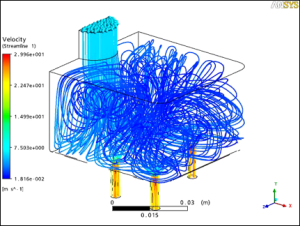

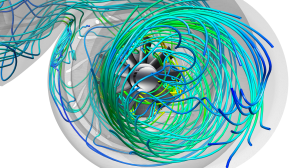

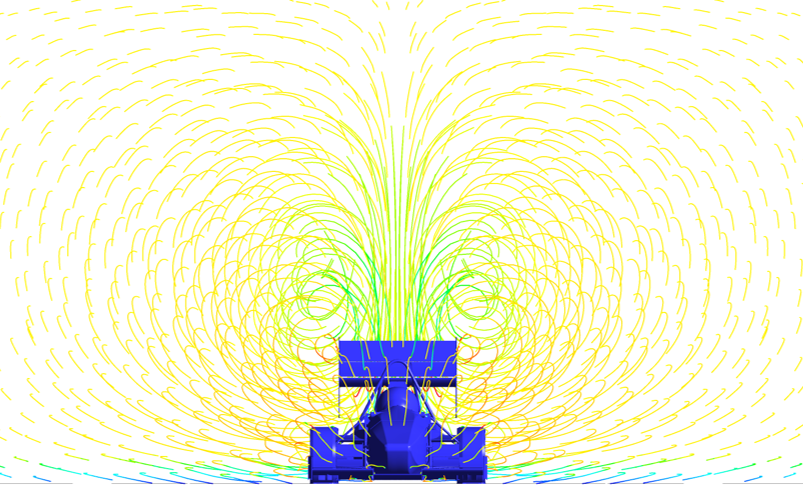

Turbulence modeling

Our fluid solutions like Fluent and CFX offer accurate simulations of fluid dynamics, providing advanced tools with a focus on turbulence modeling. Ansys' comprehensive suite of turbulence models, including the innovative GEKO model with tunable coefficients, captures complex flow behaviors across various regimes, ensuring reliable predictions for optimized engineering applications. Additionally, our solutions leverage GPU capabilities for faster computation.

Software

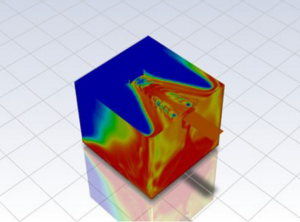

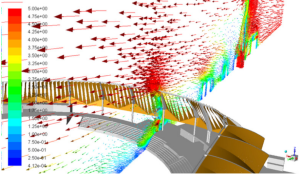

Multiphase flows

Our fluid solutions excel in simulating multiphase flows, providing advanced tools like Fluent and ParticleWorks. These solutions accurately model interactions between different phases, crucial for industries such as chemical processing, oil and gas, and power generation. By capturing complex behaviors like bubble formation, particle tracking, and phase change, Ansys enables engineers to optimize designs, improve performance, and reduce testing costs, driving innovation and efficiency in multiphase flow applications.

Software

Combustion and chemical reactions

Combustion and chemical reactions are fundamental in simulation technologies, enabling detailed analysis and optimization across various industries. Ansys Forte specializes in advanced combustion simulations for internal combustion engines, focusing on accuracy and speed. Ansys Chemkin-Pro excels in chemical kinetics, aiding in detailed reaction mechanism analysis and optimization. These simulations model reactants and products under different conditions, enhancing the development of cleaner, more efficient combustion systems for energy, automotive, and aerospace sectors.

Software

Turbomachinery design

Turbomachinery design tools in simulation technologies enable precise modeling and optimization of turbines, compressors, and pumps, enhancing performance, efficiency, and durability. Ansys CFX offers high-fidelity fluid dynamics simulations for accurate performance predictions. Ansys TurboTools provides integrated workflows and optimization. Ansys BladeModeler streamlines blade design and analysis, while Ansys TurboGrid generates high-quality meshes. CFturbo supports comprehensive design, helping innovate and accelerate development cycles.

Software

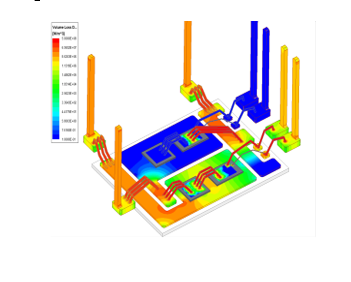

Moving particle simulations

Moving particle simulation tools, such as discrete element method (DEM) and particle-based simulation, enable detailed analysis of particle interactions and dynamics. Ansys Rocky excels in simulating bulk materials with detailed particle motion, breakage, and shape modeling. ParticleWorks specializes in fluid-particle interactions using moving particle simulation for accurate fluid dynamics analysis. These tools enhance the design and optimization of processes in pharmaceuticals, mining, and materials engineering, leading to improved efficiency and performance.

Software

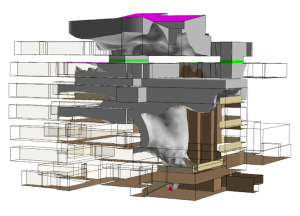

Fluid-structure interaction

Moving fluid-structure interaction (FSI) tools analyze the coupling between fluid flow and structural response, capturing dynamic interactions and force exchange to optimize designs for performance and safety. For example they are used in aircraft wing design to analyze aerodynamic forces, in hydrodynamic analysis of marine structures like ships and offshore platforms, in biomedical engineering to study blood flow in arteries, and in wind turbine blade optimization for efficiency and durability.

Software

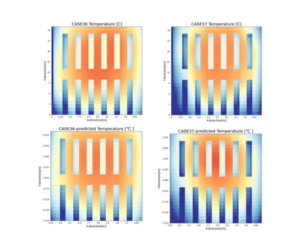

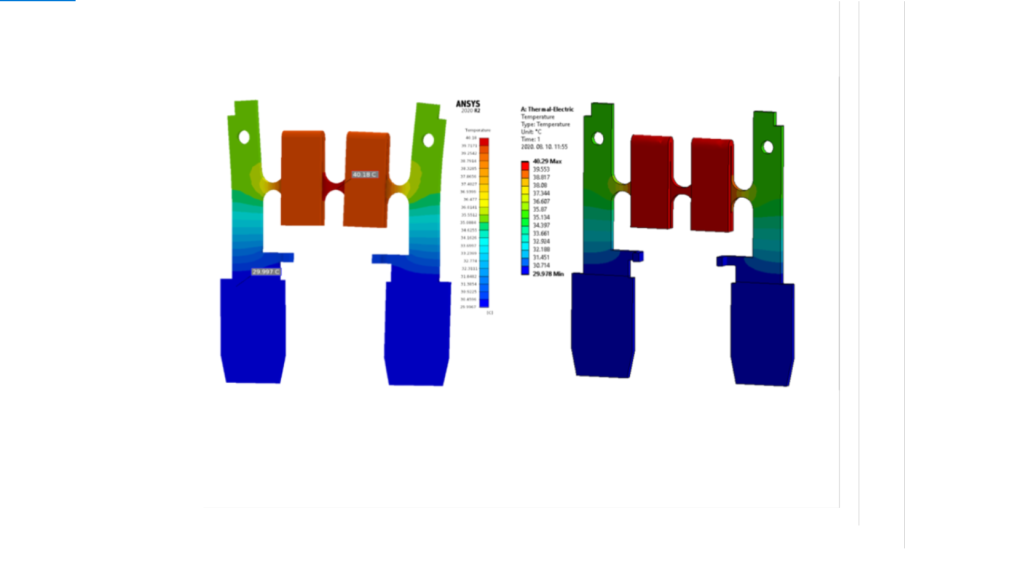

Battery modeling

Battery modeling tools in simulation technologies enable detailed analysis and optimization of battery performance, efficiency, and lifespan. These tools simulate electrochemical processes, thermal behavior, and degradation mechanisms to predict battery behavior under various conditions. Batteries can be modeled on several levels: cell level (individual cell analysis), module level (group of cells' interactions), pack level (overall battery pack performance), and system level (integration with the entire system).

Software

Injection molding

Injection molding simulation aims to detect and solve potential structural and visual product defects. Users can choose from over 9,000 commercially available polymer materials with the necessary experimental data for accurate simulation. These tools analyze pressure and temperature discrepancies, optimize process parameters and cooling layout, define venting positions, and validate warpage. Advanced modules cover hot-runner design, fiber orientation, stress analysis, and design of experiment methods to optimize processes.

Software

Blade icing

These technologies enable the analysis and prevention of ice formation on blades, crucial for aviation, wind turbines, and marine applications. These tools simulate ice accretion, thermal properties, and aerodynamic impacts to predict and mitigate icing effects. By modeling various conditions and ice protection systems, they enhance safety, performance, and reliability. Such simulations are vital for developing efficient de-icing strategies and ensuring operational integrity in adverse weather conditions.

Software

Related blog posts

Software Sales

If you have any general questions about our Ansys, Moldex3D, Dante, Particleworks, or CF Turbo simulation software (quotation, licensing, training), please contact us using one of the following contact details. Please note that our software is only available to customers from the following countries: Hungary, Slovenia, Croatia, Serbia, Bosnia and Herzegovina, Montenegro, and Macedonia.

sales (at) econengineering.com

+36 1 279 0320

Greg Lipóczi, Dr.

Commercial Director

László Molnár, Ph.D.

Academic & Key Account Representative

Péter Bara

Head of Software Sales

Key Account Manager

East Hungary

János Simon

Key Account Manager

West Hungary