Numerous possible problems and defects can arise during an injection molding process, such as the location of weld lines, air traps, hesitation, sink marks or warpage. Interested how to avoid all this?

Then get involved in solving the mysteries of injection molding simulation by attending our free webinar on Wednesday, 28 October, 2020, from 9:00 a.m., where we will show you how to avoid all these problems with Moldex3D simulation software.

Date: 28th October, 2020 (Wednesday)

Time: 09.00 – 11.30

Location: virtual, Microsoft Teams meeting

The meeting link will be sent out 24 hours before the webinar. Latest registration is possible 2 hours prior to the event.

AGENDA

09:00 – 09:15 – eCon Engineering introduction & service line overview / László Molnár, PhD, head of software service line, eCon Engineering

************

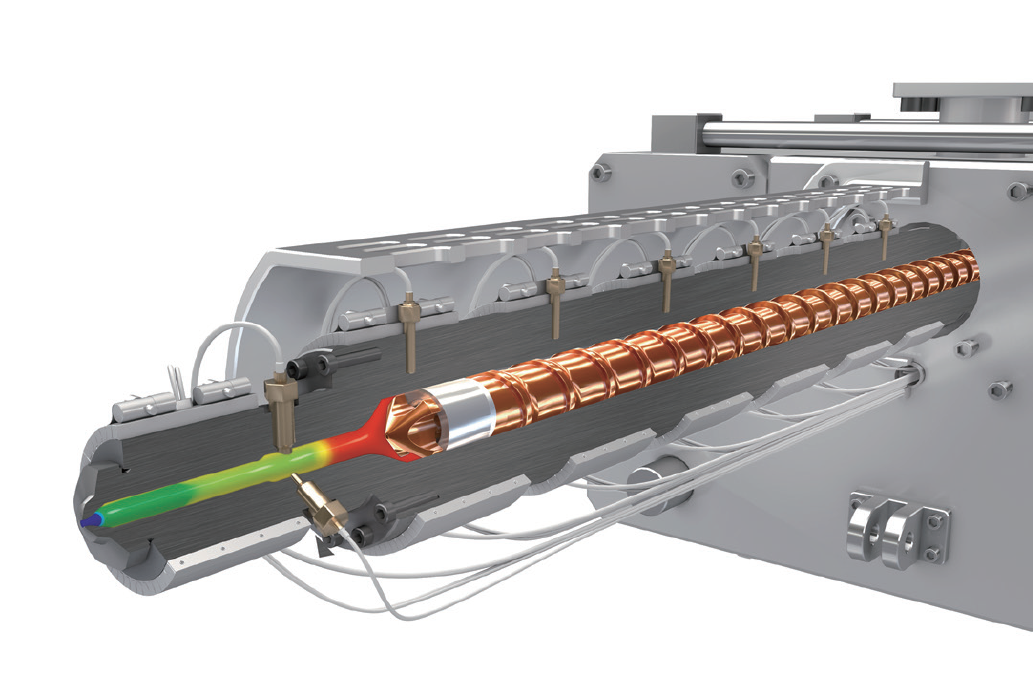

09:15 – 10:15 – Injection molding problems and their elimination, Moldex3D case studies and solutions, live demo / Péter Farkas, support engineer & Moldex3D expert, eCon Engineering

We will provide an overview of Moldex3D capabilities showing some application examples. You will get a brief insight into the simulation workflow.

You will see how Moldex3D can help tool designers and engineers to create better, safer, more efficient tools. The simulation workflow and the injection molding process settings will also be discussed. Results will be evaluated so you can see what solutions Moldex3D can offer to the designers.

************

10:15 – 10:45 – Perfect integration of smart design & smart manufacturing / Ben Wang, CoreTech System Co., Moldex3D

The presentation focuses on the improvement of the result of production through understanding your machine. It includes a series of customer success stories in this service to describe different situations people may have when manufacturing their products.

************

10:45 – 11:15 – Leveraging DOE method to get optimized injection molding parameters / Ben Wang, CoreTech System Co., Moldex3D

Determining a proper process condition is a critical point for effective injection molding, though it is also a complex process. With the Design of Experiment (DOE) method, designers/engineers can determine or evaluate the most appropriate gate location, runner size, or optimal process conditions in a short time before even going to the mold trial. It is a cost-effective approach since it replaces the conventional trial-and-error method, also able to achieve the best part quality at the same time.

************

11:15 – 11:30 – Q&A

************

The language of the webinar is English!

Let’s meet virtually on the 28th of October!