Owner: STFS TU Darmstadt | Publication date: 2022

Field of expertise:

Application area:

Industry:

The internal combustion engine is still considered as the most widely used propulsion system in the mobility sector. Nevertheless, particulates emitted from this method pose a health threat to the human body. They can cause respiratory and cardiovascular diseases, and are therefore strictly limited. In the future, these limits will likely be even stricter. Thus the design of next-generation engines requires a detailed understanding of the relevant physical and chemical phenomena inside the engine.

The Institute for Simulation of reactive Thermo-Fluid Systems (STFS) of the Technical University of Darmstadt focuses on modelling and simulating thermo-fluid processes in mechanical and chemical process engineering. In the field of combustion engine research, the institute has been successfully collaborating with Ansys Germany for many years. Their collaboration led to a significant number of publications and international visibility.

Challenges

Real Driving Emissions (RDE) measurements taken in real road traffic scenarios show that a large proportion of particulates emitted into the atmosphere during driving can be attributed to individual events. These events are characterized by highly transient engine operation. Thye are also strongly influenced by engine conditions, the vehicle’s driver, and environmental factors. To further reduce particulate emissions from the vehicle fleet in the future, it is necessary to focus on the emission peaks that occur.

Technology used

They used Ansys CFX and Ansys ICEM CFD softwares.

Engineering solution

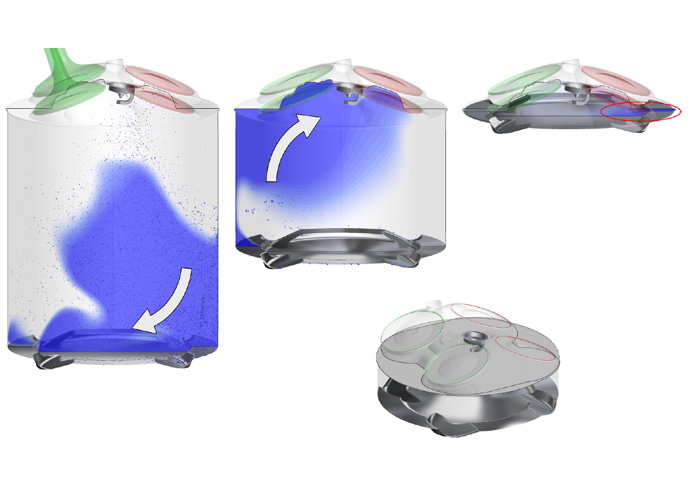

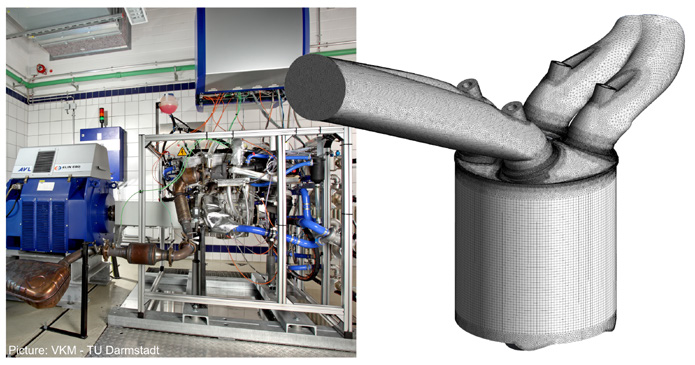

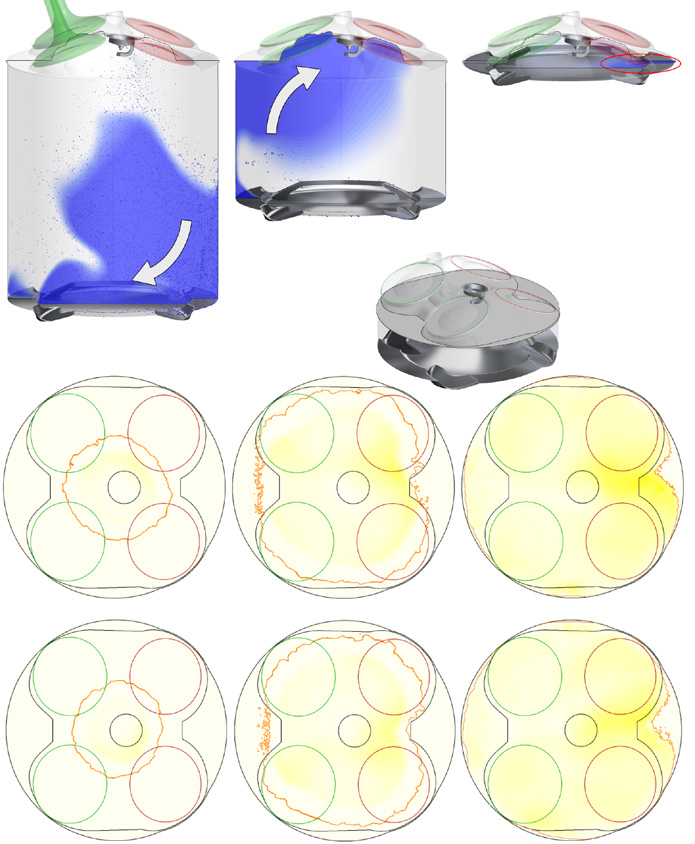

To investigate sources for particle emissions during RDE relevant transient engine operation, STFS worked together with its experimental partners. Their aim was to apply a combined experimental and numerical approach. Provided with detailed boundary conditions of the transient event, they utilized Ansys CFX coupled with moment-based soot modelling approach. They performed 3D computational fluid dynamics (CFD) in-cylinder simulations of consecutive transient engine cycles and collected insights about underlying emission-promoting effects. The tools and models for remeshing, multiphase flows, and combustion, together with additional engine specific models implemented in Ansys CFX, were crucial for this investigation.

Benefits

The simulation methodology using Ansys CFX allowed exclusive access to the processes inside a state-of-the-art series combustion engine beyond the possibilities of any conventional measurement technique. The Institute for Simulation of reactive Thermo-Fluid Systems was able to identify several causes for increased soot particle emission in the investigated events. Further simulations suggest that a reduction potential by a factor of eight is possible for selected engine cycles.

Combined experimental and numerical approach to investigate soot emission sources.

Mixture homogenization, combustion, and formation of particulate matter. The simulation methodology applied can represent the entire cause-and-effect-chain of the investigated engine cylinder.