Field of expertise:

Methods:

Application area:

Industry:

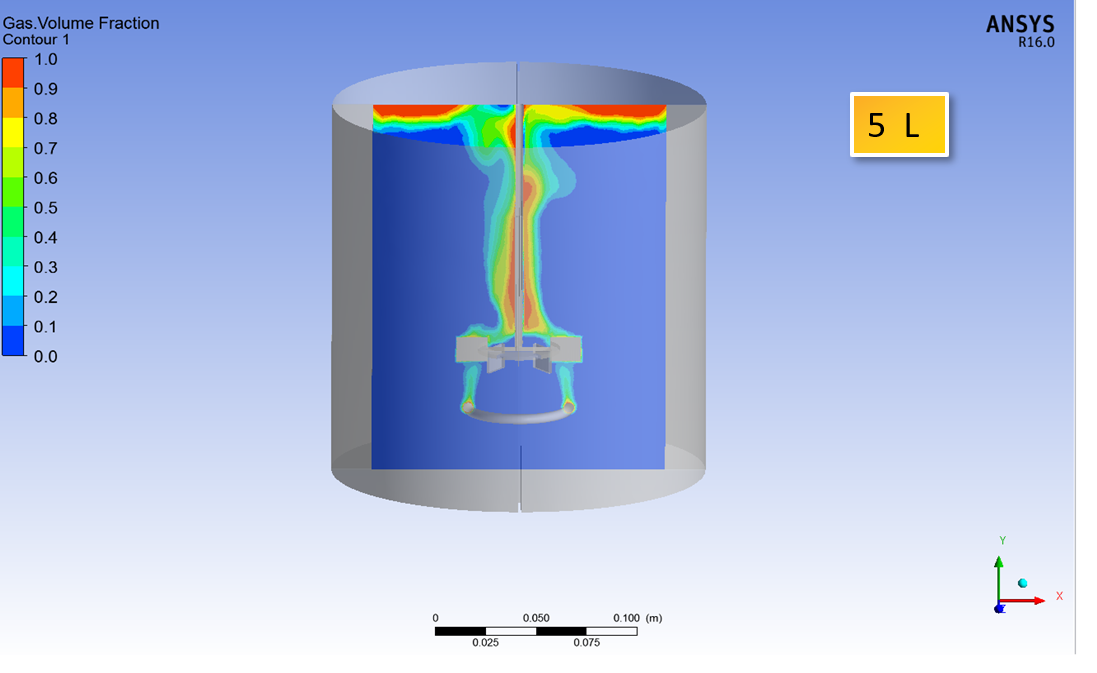

Ansys Rocky (DEM) discrete element method based simulation was used to investigate the difference in mixing resulting from the size of vessel, in this case Monod type bioreactors.

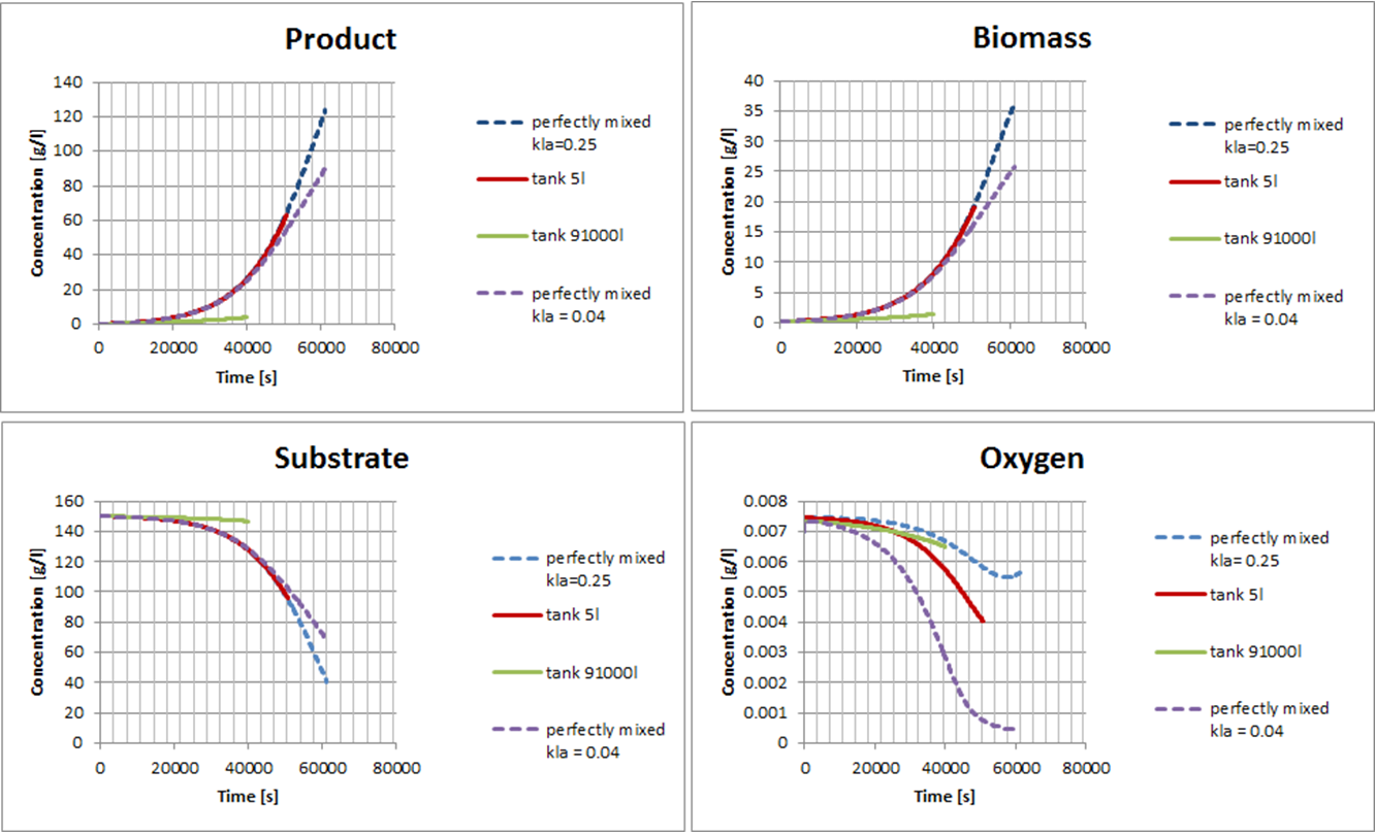

By maintain of geometrical similarities, keeping operating conditions and mixing ratios. With regard to the space contents, a significantly high similarity ratio was used so that the possible differences and phenomena resulting from this were as vivid as possible. The smaller tank is 5 l, while the larger tank is 91,000 l. 4 different materials were mixed in the tanks: Product, Biomass, Substrate and Oxygen.

On the simulation results and diagrams, we can observe that after a longer period of time, the difference is significant.

Substantial time and cost savings are achieved by triggering experiments.

kla: Volumetric mass transfer coefficient [1/s]