Field of expertise:

Methods:

Application area:

Industry:

Ansys Rocky with DEM method has been used for predicting the performance of a tablet coating process.

The coating process of a tablet’s surface can be crucial to the drug product’s effectiveness. Can be specially formulated to control how quickly the tablet dissolves and where the active drugs are absorbed after ingestion.

Optimization with scientific methods has been given precedence over traditional film coating methods. In the film coating process, a uniform coating composition is consistently sprayed onto the substrate and then dried to obtain a uniform film layer. Checking and analyzing process parameters is extremely important for qualitative tablet coating.

Efficiency of the tablet coating process, depends on the following parameters:

- drum rotational speed affecting tablet movement;

- fill level;

- number of sprays;

- tablet shape;

- air flow and cooling of spray drops on the tablet.

In order to evaluate and increase the efficiency of the coating process, following output quantities can be analyzed:

- velocity distribution in spray zone (1);

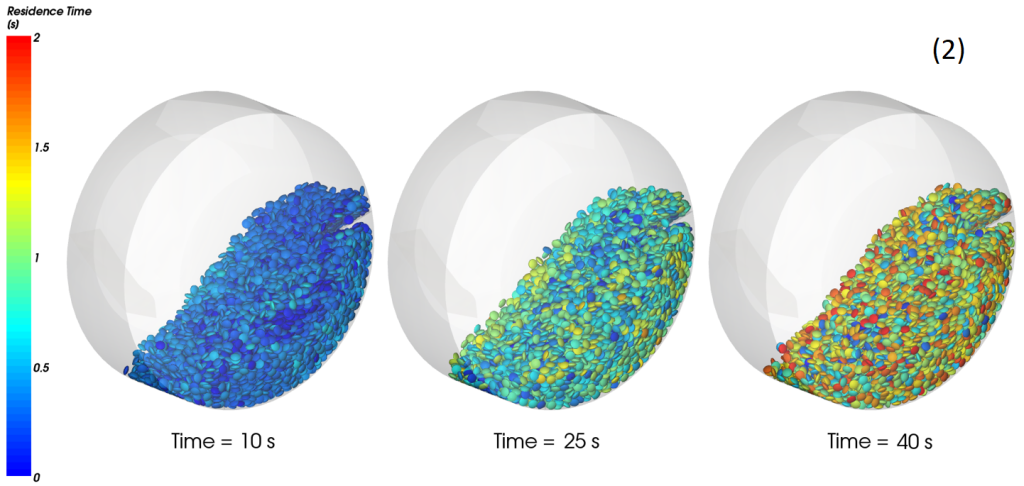

- residence time distribution in spray zone (2);

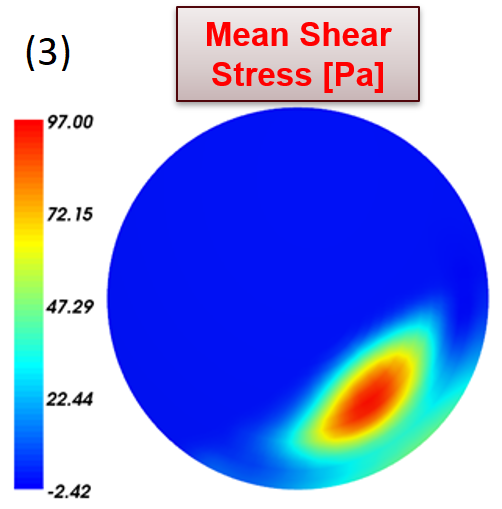

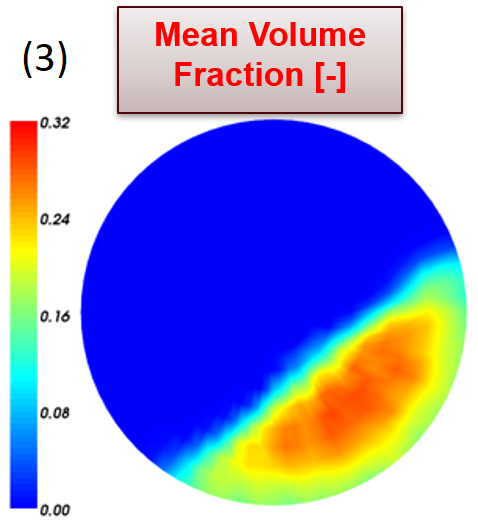

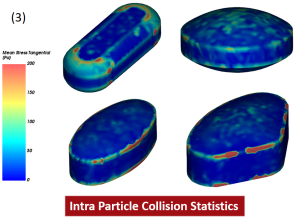

- inter-tablet coating variability (3);

- number of spray guns or spray zones (4).