Owner: Ethicon

Field of expertise:

Methods:

Application area:

Industry:

About the company

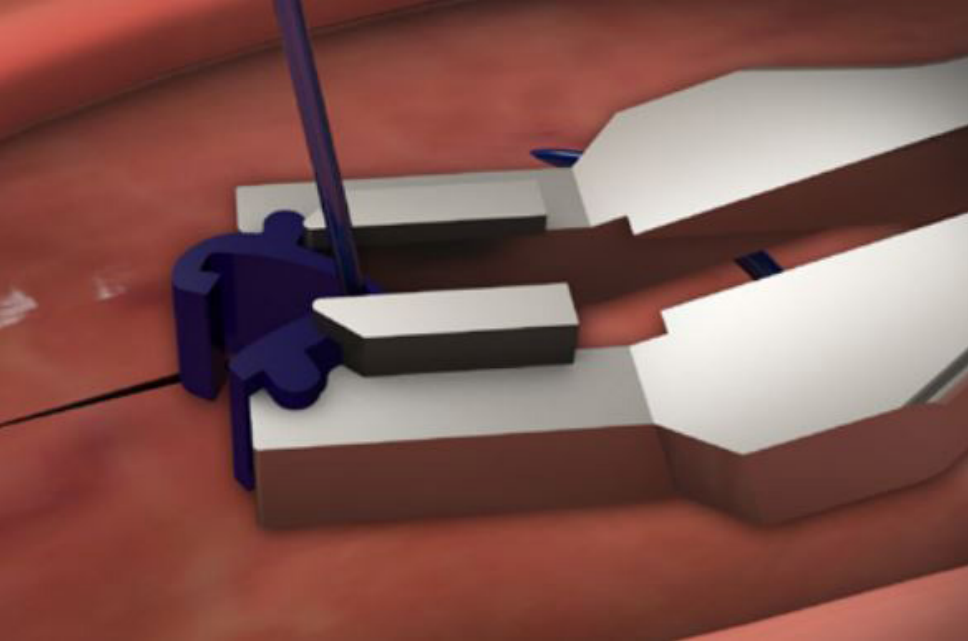

Ethicon, as part of Johnson & Johnson Medical Devices Companies, is a medical company, that has revolutionized surgery from creating the first sutures to starting minimally invasive procedures.

Challenges

Biocompatibility of medical devices is crucial for patients’ safety. Therefore, rapid selection of materials used for manufacturing such devices is critical for production of a compatible medical device while keeping supply chain continuity and minimizing risks of lack medical devices after any regulatory change. At the same time, developers of new medical devices have to be able to access previously existing medical data. Only with all of this, it is possible to accelerate new medical product development.

Technology used

Engineering solution

Ethicon used Ansys Granta MI™ Enterprise to digitalize and migrate both standard and customized material data to a centralized database. Due to this, employees have quick access to all the materials information, device-level material contents, as well as where certain material is used across the company. Furthermore, it made it possible to assess the device risk by using Restricted Substances functionality of Granta software, and to enable this data to be accessible from within Ethicon’s engineering tools available to their global engineering teams. For approval and review of materials, standardized Granta MI workflows were developed. This made it easier to validate name changes of materials coming from vendors.

Benefits

To sum up, it is now possible to select in a rapid way manufacturing materials for medical devices, to ensure their biocompatibility and that they do not contain any restricted substances. Supply change continuity is not interrupted by regulation changes or vendor changes. Repeat testing is avoided by enabling access to history of materials testing and biocompatibility. This brought significant savings in time and money needed to invest in material processes.

Surgical equipment

Surgery