Ansys offers powerful structural analysis software for engineers to swiftly address complex engineering challenges. Our tools support highly customizable finite element analyses (FEA), enabling automated examination of diverse design scenarios. Early adoption streamlines processes, cuts costs, minimizes design iterations, and accelerates product launches. Our comprehensive suite facilitates simulations for shock, vibration, impact, occupant safety, heat transfer, and fatigue, addressing varied product challenges. Ansys Structural analysis provides versatile solutions for diverse engineering hurdles and seamlessly integrates with other products for multidisciplinary simulations. Engineered with advanced capabilities and a user-friendly interface, Ansys Structural products ensure accurate insights for informed design decisions. Their adaptability across industries - such as aerospace, automotive, civil engineering, and manufacturin - makes them invaluable for conquering intricate structural problems efficiently.

- Persistent, dependable solver technology

- Simulate extreme deformation problems

- Implicit integration method for stable results

- Build preparation and process simulation

- Embedded material libraries

- Sound quality with psychoacoustic criteria

- Material response of high pressure eplosions

- Accumulated damage from repetitive strain

- Predict a product's lifetime

- Process-driven design

- Simulate entire die process

- Minimize the risks of additive manufacturing

- Life prediction for electronic hardware

- Fine tune product acoustics

- In-depth analysis of structural behavior

- Accurate evaluation of physical events

- Multibody dynamic solver

- Tackle highly nonlinear simulations

Capabilities

Ansys offers powerful structural analysis software to address complex engineering challenges swiftly. Our tools support highly customizable finite element analyses (FEA), enabling automated examination of diverse design scenarios. Early adoption streamlines processes, cut costs, minimizes design iterations, and accelerates product launches. Our comprehensive suite facilitates simulations for shock, vibration, impact, occupant safety, heat transfer, and fatigue, addressing varied product challenges. Ansys Structural analysis provides versatile solutions for diverse engineering hurdles and seamlessly integrates with other products for multidisciplinary simulations. Engineered with advanced capabilities and a user-friendly interface, Ansys Structural products ensure accurate insights for informed design decisions. Their adaptability across industries - such as aerospace, automotive, civil engineering, and manufacturing - makes them invaluable for conquering intricate structural problems efficiently.

Explore our capabilities!

Ansys Workbench

Ansys Workbench enables you to perform coupled field or so called multiphysics simulations. It can make connections between different physics-based analysis systems,including fluid, electromagnetic and thermal related softwares, moreover optimization of the solution is also possible through the modification of different design and load parameters. The geometry of the model can be almost any kind of CAD file format popular in the industry.

Software

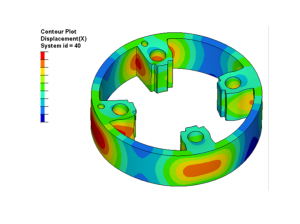

Strength analysis

The strength of the geometric composition and the material of the components that make it up greatly influence the behavior - operation performance, expected service life - of the product. Large deformation and stress, which can come from mechanical, thermal and electromagnetic loads - like pressure, bolt pretension, forces - are potential sources of danger, which must be taken into account before placing the product on the market.

Software

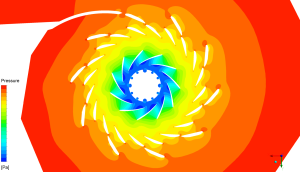

Vibration analysis

Ansys software offers a comprehensive suite of tools for vibration analysis, crucial in considering environmental and operational-induced vibrations. These encompass a spectrum of sources like acoustic waves, transportation, seismic events, and harmonic loads from rotational motions. Understanding and managing these vibrations are pivotal as they profoundly impact the lifecycle, fatigue, and overall durability of structures and systems.

Software

Thermal analysis

The effects of heat and thermal management on parts and assemblies is becoming increasingly critical as performance limits are pushed further by the need to have lighter, smaller and more efficient designs. Convection, radiation and conduction loads are obvious, but the need to include the effect of power losses and thermal energy from friction and external sources such as pipe flows means that analysts need to have more tools at their disposal to simulate thermal models accurately.

Software

Durability

Building durable products is key to reducing warranty costs and increasing reliability. Ansys software offers robust durability capabilities, enabling comprehensive analysis to anticipate and mitigate potential issues. This proactive approach not only helps in cost reduction by minimizing additional expenses, such as those associated with extended warranties. Fatigue or lifing analysis is a key enabler in building this product durability knowledge.

Software

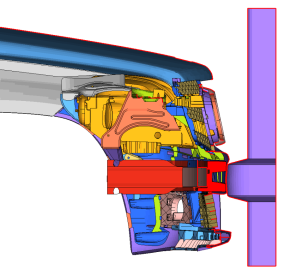

Impact

Ansys software offers the ability to model various types of impacts - such as drop, shock, smash, and crash - using mechanical, explicit, and rigid body dynamics solutions tailored within its suite of software offerings. Drop tests are ideal candidates for an impact analysis. These impact analysis programs calculate the forces between two or more colliding bodies and the resultant deformation or damage.

Software

Structural optimization

3D printing or additive manufacturing has become a widely adopted technology in manufacturing. The emphasis on lightweighting models and swiftly extracting CAD files is crucial. Ansys software allows for the exploration of designs and process parameters specifically tailored for additive manufacturing. Through Ansys tools, engineers can engage in parametric optimization, shape optimization through mesh morphing, and topology optimization to refine and enhance the efficiency of their designs.

Software

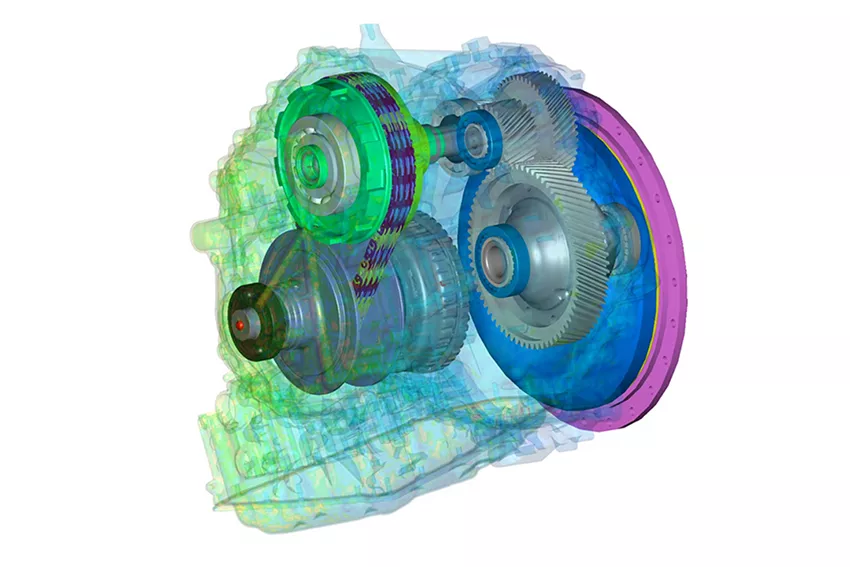

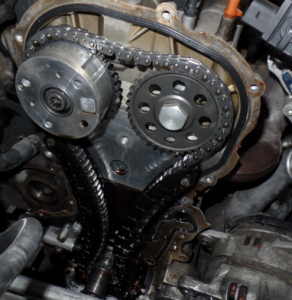

Rigid and Multi Body Dynamics

Mechanical devices can contain complex assemblies of interconnected parts undergoing large overall motions. Examples could include suspension assembles in ground vehicles, robotic manipulators in manufacturing processes or gear systems within electric drivetrains. Simulating the motion of these systems gives insight into their performance over the range of dynamic loading experienced when in operation.

Software

Hydrodynamics

Offshore structures are subjected to environmental loading from the effects of waves, currents and wind. The design requirements for these structures can be quite different from traditional land-based constructions. Simulating the loading and the effects of these factors on structural response is a necessary component of the design. Ansys software offers high-fidelity solutions tailored for simulating models within fluid loading environments, predicting responses, and side effects accurately.

Software

Composites

Composite materials have a very favorable properties – light, strong and versatile – these make them attractive for many types of manufacturing. Its most widespread representative is the carbon fiber which can be found in construction machines, vehicle manufacturing (aerospace, automotive, marine), energy and sports equipment. Their composite nature, however, makes accurate simulation a challenge. Ansys offers a complete suite of tools to help you overcome this challenge.

Software

Additive manufacturing

Ansys provides a robust and comprehensive solution for the entire Additive Manufacturing process. Starting from Design for Additive Manufacturing (DfAM), encompassing material analysis, print design, process simulation, and validation, it facilitates the realization of precise specifications outlined by designers and engineers. This integrated suite empowers the creation of an ideal product, ensuring alignment with exacting standards and requirements.

Software

Sould of multiphysics simulation results

Listen to many Ansys simulations calculation results and create sound from spectra or waterfall resulting from mechanic, aerodynamic or fluid simulations. You can listen to the sound from the acoustic simulation of an electric motor dynamic model and then modify sounds to evaluate effects of level changes on components, all while running a study on sound quality.

Software

Related blog posts

Software Sales

If you have any general questions about our Ansys, Moldex3D, Dante, Particleworks, or CF Turbo simulation software (quotation, licensing, training), please contact us using one of the following contact details. Please note that our software is only available to customers from the following countries: Hungary, Slovenia, Croatia, Serbia, Bosnia and Herzegovina, Montenegro, and Macedonia.

sales (at) econengineering.com

+36 1 279 0320

Greg Lipóczi, Dr.

Commercial Director

László Molnár, Ph.D.

Academic & Key Account Representative

Péter Bara

Head of Software Sales

Key Account Manager

East Hungary

János Simon

Key Account Manager

West Hungary