In modern metal technologies, the ability to predict and optimize processes such as casting, welding, forming, and additive manufacturing is crucial. Our simulation tools provide the necessary insights to manage complex material behavior during manufacturing, such as heat transfer, phase changes, and mechanical stresses. These tools support a range of operations, from simulating casting distortion and residual stress in heat-treated parts to optimizing welding sequences and additive manufacturing builds. With features like topology optimization, automated distortion compensation, and phase transformation modeling, they ensure efficient workflows. With enhanced control over material behavior and process dynamics, these solutions ensure that each step of the metal production workflow is optimized for precision and quality.

- Solution for metal casting, welding, and forming

- Easy-to-use tools for process optimization

- Distortion and stress prediction

- Multi-phase material behavior

- Heat treatment effects

- Welding sequences enhancement

- Analyze thermal and structural behavior

- Model phase changes

- Material behavior prediction in additive manufacturing

- Auto-generated supports for additive processes

- Real-time process feedback

- Carburizing and nitriding

- Residual stress prediction

- Heat transfer and material flow simulation

- Detailed material property tuning

- Sintering and fusion processes

- Welding and forming optimization

Capabilities

Offering versatility and scalability, Ansys and Cast Designer solutions form a comprehensive software suite aimed at minimizing risks and guaranteeing the creation of high-quality, certified parts. The software's multifaceted features streamline the additive manufacturing, casting, forming, welding, and heat treatment process, providing a strong foundation for accurate part production. It upholds strict quality standards, minimizing potential challenges.

Explore our capabilities!

Design for AM (DfAM)

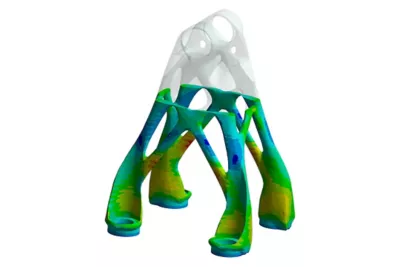

Ansys integrates essential tools for optimized production in Design for Additive Manufacturing (AM). CAD modeling establishes precise designs, a foundational step, seamlessly transitioning to advanced features like topology optimization. This refines designs, ensuring sturdy structures with minimal material usage. The software excels in Lattice and Lightweighting techniques, enabling complex structures while reducing weight without compromising strength.

Software

Build setup

Ansys offers a comprehensive setup capability crucial for seamless manufacturing. It begins with STL file repair and geometry manipulation, ensuring flawless 3D printing processes. Optimization of material usage and simultaneous printing of multiple components are achieved through part nesting and support generation in Ansys. Additionavlly, Ansys offers orientation guidance and user-friendly wizards, facilitating optimal positioning and setup to achieve superior printing outcomes.

Software

AM process simulation

Ansys simulation provides essential capabilities for accurate manufacturing processes. The simulations of metal additive manufacturing processes in Ansys optimize intricate steps, ensuring both efficiency and high-quality outcomes. The inclusion of distortion compensation in Ansys mitigates potential deformations, ensuring the precision of the production process. Moreover, Ansys incorporates Build Failure Prediction, identifying potential issues in advance and allowing preemptive measures to enhance overall manufacturing reliability.

Software

Formability and Springback Analysis

Simulating material deformation during metal forming is essential for evaluating performance and predicting potential failures. This capability models stress distribution across the metal surface and tracks strain levels to identify areas prone to defects such as necking, or cracking with the help of FLD diagrams. By integrating detailed material models, the simulation provides insight into how the material behaves under complex loading conditions. The system also evaluates elastic recovery after forming, accurately predicting springback behavior.

Software

Drawbead and Binder Force Definition

Managing material flow during forming processes requires precise control of drawbeads and binder force. This feature enables the accurate simulation of drawbead-induced resistance, allowing engineers to evaluate how different bead designs impact material movement. The binder force is simulated with equal precision, providing insight into its effects on maintaining surface integrity and controlling material wrinkling or stretching. By adjusting these parameters, engineers can optimize material flow and prevent common issues such as tearing or buckling.

Software

Comprehensive Shaping Solutions

Our solution covers a broad range of shaping processes, from hydroforming to tube bending and part transfer, allowing engineers to simulate these tasks with high precision. The ability to model complex forming operations under various loading conditions helps in optimizing tool geometry and material behavior. The simulation offers detailed insights into material flow, stress distribution, and deformation characteristics, ensuring that the final part shape adheres to stringent quality standards.

Software

Advanced Heat Treatment Simulation

Combining thermal analysis with carbon/nitrogen diffusion and solid mechanics, this approach accurately models heat treatment processes and material behaviour. Predict phase transformations, residual stresses, and material properties to understand component performance under various conditions!

Software

Multiphase Constitutive Modelling

Utilize a multiphase constitutive model integrated with phase transformation kinetics, allowing detailed simulation of material behavior during heat treatment. This integration enables you to understand how phase changes influence mechanical properties, stress distribution, and overall material performance.

Software

Controlling Residual Stress and Strain

Predict and manage residual stress to enhance the structural integrity and fatigue life of your treated parts. Accurate stress predictions help you mitigate risks associated with stress concentrations, reducing the likelihood of failures and extending the service life of critical components.

Software

Casting system design for various processes

Cast-Designer enables advanced casting system design for various processes, including high-pressure die casting (HPDC), gravity die casting (GDC), and low-pressure die casting (LPDC). The software simplifies the design of risers, gates, and feeders, and integrates fully with CAD systems to streamline the entire process, from initial design to production, offering flexibility and adaptability across different casting techniques while minimizing production issues and maximizing quality.

Software

Multi-criteria non-linear parameter optimization

With Cast-Designer’s multi-criteria non-linear parameter optimization, You can handle multiple design variables like CAD geometries, material properties, and process settings. Using advanced AI-driven techniques such as DOE, GA, and PSO, the software intelligently optimizes parameters to reduce errors, enhance precision, and achieve the desired outcomes in the most efficient way possible, significantly improving overall design and production quality.

Software

Cooling system design

The cooling system design feature in Cast-Designer includes powerful integrated analysis tools that enable users to design efficient cooling channels for precise thermal control. You can simulate the effects of cooling on the casting process, predicting key outcomes such as shrinkage, stress distribution, and thermal deformation. With an optimized cooling system, You can reach greater thermal stability, shorter cycle times, and higher-quality castings.

Software

Coupled thermal, flow, stress, and micro-structure solvers

The solvers in Cast-Designer Weld allows You to model complex interactions between heat transfer, material flow, mechanical stress, and microstructural evolution during welding. By capturing these complex interactions, the software provides predictions of residual stresses, deformations, and material transformations, which are critical for understanding the effects of welding on the structural integrity of components.

Software

Welding sequence and assembly simulation

Cast-Designer Weld provides comprehensive welding sequence and assembly simulation, enabling users to simulate the entire welding process for complex assemblies. This feature allows for detailed analysis of the effects of different welding sequences on the final structure, such as distortion and residual stress. By optimizing the sequence, users can minimize unwanted outcomes like warping and improve the quality of the assembly, ensuring better alignment and structural integrity.

Software

Advanced welding optimization using AI (DOE, GA, PSO)

With advanced AI -driven tools like Design of Experiments (DOE), Genetic Algorithms (GA), and Particle Swarm Optimization (PSO), Cast-Designer Weld provides powerful optimization for complex welding processes. These techniques automate the adjustment of variables such as welding speed, heat input, and material properties, helping users achieve their desired outcomes with minimal manual intervention. The optimization process involves multiple iterations where AI evaluates each configuration to minimize defects such as distortion and residual stress.

Software

Software Sales

If you have any general questions about our Ansys, Moldex3D, Dante, Particleworks, or CF Turbo simulation software (quotation, licensing, training), please contact us using one of the following contact details. Please note that our software is only available to customers from the following countries: Hungary, Slovenia, Croatia, Serbia, Bosnia and Herzegovina, Montenegro, and Macedonia.

sales (at) econengineering.com

+36 1 279 0320

Greg Lipóczi, Dr.

Commercial Director

László Molnár, Ph.D.

Academic & Key Account Representative

Péter Bara

Key Account Manager

East Hungary

János Simon

Key Account Manager

West Hungary