Dante Solutions: Advanced Heat Treatment Simulation

Discover the power of an advanced tool that revolutionizes component and process design through heat treatment simulation. This comprehensive solution combines a multiphase constitutive framework with phase change kinetics, allowing you to accurately phase transformations, component distortion, and material hardness. Demonstrated effectively in complex, real-world applications, it provides essential insights for optimizing carburizing and nitriding schedules. Manage residual stresses and microstructural evolution while evaluating the effects of process and design modifications on heat treatment outcomes. By leveraging this technology, you can enhance part performance and ensure reliability, making it an invaluable asset for engineers and metallurgists seeking to optimize their heat treatment processes.

- Integrated Thermal, Diffusion, and Solid Mechanics Simulation

- Multiphase Constitutive Model

- Residual Stress and Strain Analysis

- Distortion Prediction

- Customizable Heat Treatment Cycles

- Material Database

- Automatic Time Stepping

- Comprehensive Reporting

- User-Friendly Interface

- Multi-Scale Modeling

- Support for Multiple Simulation Scenarios

Check out the key features of Dante Solutions

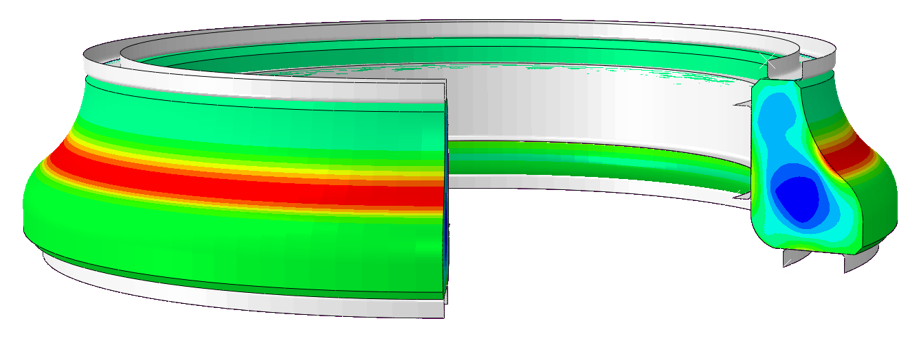

Advanced Heat Treatment Simulation

Combining thermal analysis with carbon/nitrogen diffusion and solid mechanics, this approach accurately models heat treatment processes and material behaviour. Predict phase transformations, residual stresses, and material properties to understand component performance under various conditions!

Multiphase Constitutive Modeling

Utilize a multiphase constitutive model integrated with phase transformation kinetics, allowing detailed simulation of material behavior during heat treatment. This integration enables you to understand how phase changes influence mechanical properties, stress distribution, and overall material performance.

Controlling Residual Stress and Strain

Predict and manage residual stress to enhance the structural integrity and fatigue life of your treated parts. Accurate stress predictions help you mitigate risks associated with stress concentrations, reducing the likelihood of failures and extending the service life of critical components.

Carburization and Nitriding

Design low-pressure carburization and nitriding schedules. Leverage comprehensive material databases, diffusion, and nitride morphology models to handle various geometries and control parameters, ensuring accurate carbon and nitrogen distribution for desired hardness profiles and optimized metallurgical properties.

Thermal Process Simulation

Employ phase transformation and mechanical data from the DANTE material database to support various process definitions, including time-temperature data entry and calculated heating/cooling cycles. These tools provide detailed outputs on hardness, phase evolution, and material performance across multiple heat treatment scenarios.

Distortion Prediction

It's important to check distortion of components undergoing heat treatment. Simulate accurately how heat treatment processes affect material and geometry during cooling, which is crucial for predicting and optimizing manufacturing outcomes!

Process Optimization and Impact Evaluation

Optimizing carburizing and nitriding schedules assesses the impact of process and design changes on heat treatment outcomes. Specialized features offer insights into material modifications, ensuring desired properties without adverse effects. Precisely controlling diffusion processes achieves improved, tailored case hardening.

Material Database

Material Database is a comprehensive repository of material properties for advanced heat treatment simulations. It includes data on phase transformation kinetics, mechanical properties, and thermal behaviors.Essential for precise modeling of phase fractions, hardness profiles, and stress states, it ensures accurate results.

Software Sales

If you have any general questions about our Ansys, Moldex3D, Dante, Particleworks, or CF Turbo simulation software (quotation, licensing, training), please contact us using one of the following contact details. Please note that our software is only available to customers from the following countries: Hungary, Slovenia, Croatia, Serbia, Bosnia and Herzegovina, Montenegro, and Macedonia.

sales (at) econengineering.com

+36 1 279 0320

Greg Lipóczi, Dr.

Commercial Director

László Molnár, Ph.D.

Academic & Key Account Representative

Péter Bara

Key Account Manager

East Hungary

János Simon

Key Account Manager

West Hungary