Solution for complex large welding and assembly process simulation

Cast-Designer Weld provides comprehensive welding simulation by coupling thermal, flow, stress, and micro-structure solvers, featuring automatic mesh generation, advanced CFD solver, and a rich heat source model. Discover the robust tools for welding sequence design, weld bead creation and automatic optimization using Design of Experiments (DOE), Genetic Algorithms (GA), and Particle Swarm Optimization (PSO) methods to easily identify the best welding parameters. With a built-in database, You can leverage over 400 material options, including various steels, aluminums, and exotic alloys. The unique mesh technology supports hexahedral and tetrahedral meshing, providing high accuracy and efficiency. Cast-Designer ensures precise and efficient welding simulations, try out this essential tool for Your advanced welding applications!

- Evaluate residual distortions and stresses

- Control the HAZ

- Weld bead prediction

- Optimize the welding sequence

- Several welding technologies

- Parallel computing capbilities

- Microstructure prediction

- Weldability Calculator

- High accuracy and stability

- Cost optimization tools

Check out the key features of Cast-Designer Weld

Comprehensive Welding Analysis and Optimization

Try features for determining weldability, cooling time and filler metal quantities. Optimization tools provide advanced analysis and optimal schedules for CO2 laser, pulsed Nd YAG, and arc welding. Compute optimal procedures for various welding processes and gain insights into temperatures, weld sizes and material effects!

Multi-pass weld design and simulation

Optimize welding sequences and designs through computer modeling, automate pattern selection to minimize distortion and residual stress! Use surrogate modeling to efficiently identify the best pattern from thousands of possible configurations, ensuring optimal multi-pass welding joints and enhancing fracture resistance!

Weld Pool Simulation

The CFD solver in Cast-Designer accurately simulates transient temperature distributions in the weld pool, accounting for surface tension effects, buoyancy forces, and free surface motion. This detailed simulation captures all relevant physical phenomena for realistic process modeling.

Joint database for thermal calibration

Explore the comprehensive joint database for MAG/MIG, laser welds, and aluminum, with over 30 welding joint types, adaptable for specialized applications, aiding in accurate heat transfer calibration during welding simulations. Take advantage of parallel computing both for CFD and FEM solvers!

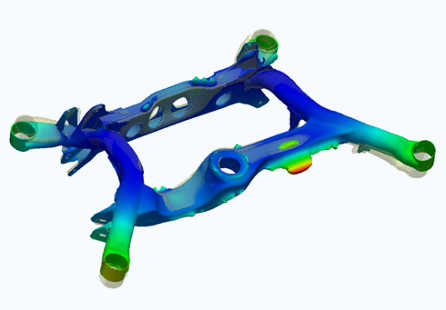

Evaluate whole welded assemblies

Our solution simplifies welding assembly simulations for large structures, allowing You to focus on process design without needing expertise in non-linear finite element simulation. Handle thermal cycles, material changes, stresses, and more! GANTT diagrams optimize welding sequences, cooling, and clamping times.

In-depth cost calculation and report generation

The quotation module calculates welding costs, including technical and commercial parameters, for price estimation and production cost control. Users can customize currency, process, and manpower costs, generating detailed cost reports and multi-language quotation sheets in Excel.

Simulate wide range of welding technologies

Simulate resistance spot welding with accurately coupled electromagnetism, heat transfer, metallurgy, and mechanics. Check friction stir welding modelling using thermo-fluid and thermo-mechanical formulations, predicting residual distortions, stresses, and microstructures by simulating material stirring and heat generation.

Optimize weld parameters with advanced tools

The optimizer leverages advanced AI techniques like DOE, GA, and PSO for multi-criteria non-linear optimization. Address various targets such as minimizing distortion, residual stress, and maximizing welding speed! You can handle multiple design variables, including CAD geometries, material properties, and welding parameters!

Software Sales

If you have any general questions about our Ansys, Moldex3D, Dante, Particleworks, or CF Turbo simulation software (quotation, licensing, training), please contact us using one of the following contact details. Please note that our software is only available to customers from the following countries: Hungary, Slovenia, Croatia, Serbia, Bosnia and Herzegovina, Montenegro, and Macedonia.

sales (at) econengineering.com

+36 1 279 0320

Greg Lipóczi, Dr.

Commercial Director

László Molnár, Ph.D.

Academic & Key Account Representative

Péter Bara

Key Account Manager

East Hungary

János Simon

Key Account Manager

West Hungary