Predict Stress & Distortion in the AM Process with Ansys Additive Print

Ensure accurate production from the start with Additive Print, assess distortion, stress, and strain areas, and anticipate blade crashes. Various fidelity levels enable a quick estimation or a detailed thermal analysis. Eliminate the guesswork by achieving insights into part behavior during production and take corrective measures for accurate first-time results. Make your workflow easier removing uncertainties and time wastage! This user-friendly solution helps you to save time while ensuring part quality. It is effortless to upload supports from other software tools and pick additional materials (like Al357, AlSI10Mg, and more) for detailed thermal simulations. Recent upgrades enable reading build files from machine manufacturers like EOS and SLM, along with wizards for seamless result transfer to Ansys Workbench Additive.

- Predict Distortion

- Predict Stress

- Auto Distortion Compensation

- Predict Thermal Strain

- Auto Generate Supports

Check out the key features of Ansys Additive Suite

Predict Distortion

Distortion prediction offers a visual depiction of how parts might deform during the building process. Use Additive Print's distortion abilities to assess assumptions, aiding in the effective choice of part orientations and support strategies.

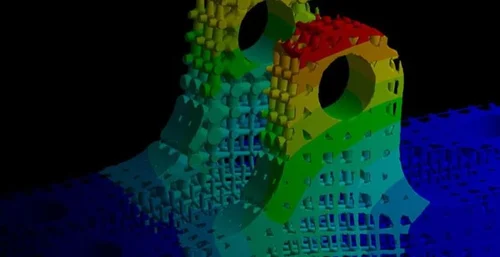

Predict Stress

Additive Print utilizes graphical visualization to depict layer-by-layer stress buildup, enabling the anticipation of trends and final residual stress throughout the build. Through color mapping, it predicts potential locations of blade crashes.

Auto Distortion Compensation

Use the automatic Distortion Compensation feature to generate distortion-compensated STL files, ensuring precise part production in one go! Minimize errors and maximize efficiency with this feature to achieve high-quality parts with exceptional dimensional accuracy!

Predict Thermal Strain

Ansys Additive Print software's capability empowers users to forecast thermal strain accurately. It enables the assessment of anisotropic effects and computes strain patterns effectively, providing valuable insights for optimizing designs and ensuring structural integrity in additive manufacturing processes.

Auto Generate Supports

Additive Print offers automated support generation, aiding in predicting the maximum residual stresses the supports need to endure. The algorithm adjusts support density to manage these stresses effectively. Users receive the resulting support structure in STL file format for reference.

Software Sales

If you have any general questions about our Ansys, Moldex3D, Dante, Particleworks, or CF Turbo simulation software (quotation, licensing, training), please contact us using one of the following contact details. Please note that our software is only available to customers from the following countries: Hungary, Slovenia, Croatia, Serbia, Bosnia and Herzegovina, Montenegro, and Macedonia.

sales (at) econengineering.com

+36 1 279 0320

Greg Lipóczi, Dr.

Commercial Director

László Molnár, Ph.D.

Academic & Key Account Representative

Péter Bara

Head of Software Sales

Key Account Manager

East Hungary

János Simon

Key Account Manager

West Hungary