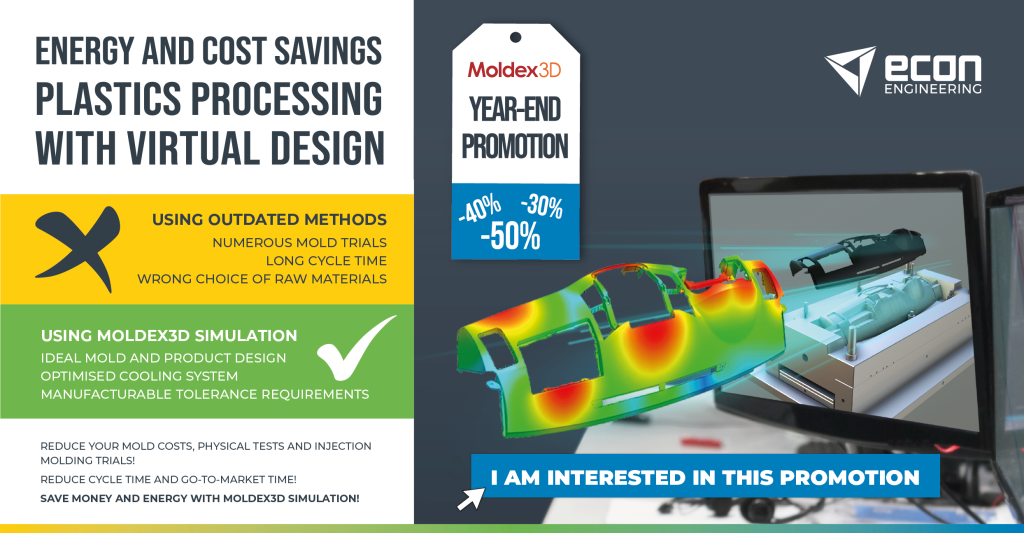

Now it’s a double benefit choosing Moldex3D simulation tool for virtual design. Less mold try-out, shorter cycle time, ideal material selection and a perfect final product.

The level of energy consumption in plastics processing is nowadays very important. Due to the large number of mold try-out, outdated methods are extremely expensive and time-consuming. Virtual design offers a significant competitive advantage and cost reduction for the plastics processing industry, both in the development of molds and plastic products.

A wide range of engineering simulation tools is available to Moldex3D customers, with significant discounts on these simulation software products until the end of 2022. As a Moldex3D channel partner, eCon Engineering Kft. is committed to supporting and serving the engineering community in the plastics industry. eCon’s software support engineers offer free and extensive information on the beneficial opportunities to those interested who register on the website.

In addition to the Moldex3D year-end promotion, the webinar on 17 November will cover mold development in virtual environment and how to avoid plastic product development mistakes. The online training is free to attend but registration is required.

Registration for Moldex3D promotion

You can read our Privacy Statement by clicking on this link, and also you can find it on our website.

If you have further question in connection with the promotion, please feel free to contact us at sales (at) econengineering.com!