Field of expertise:

Methods:

Application area:

Industry:

Area:

Quality control based on various parameters. The equipment is suitable for checking the parameters requested by the customer or manufacturer, using rule-based systems or even image-based analyzes supported by artificial intelligence.

Solution:

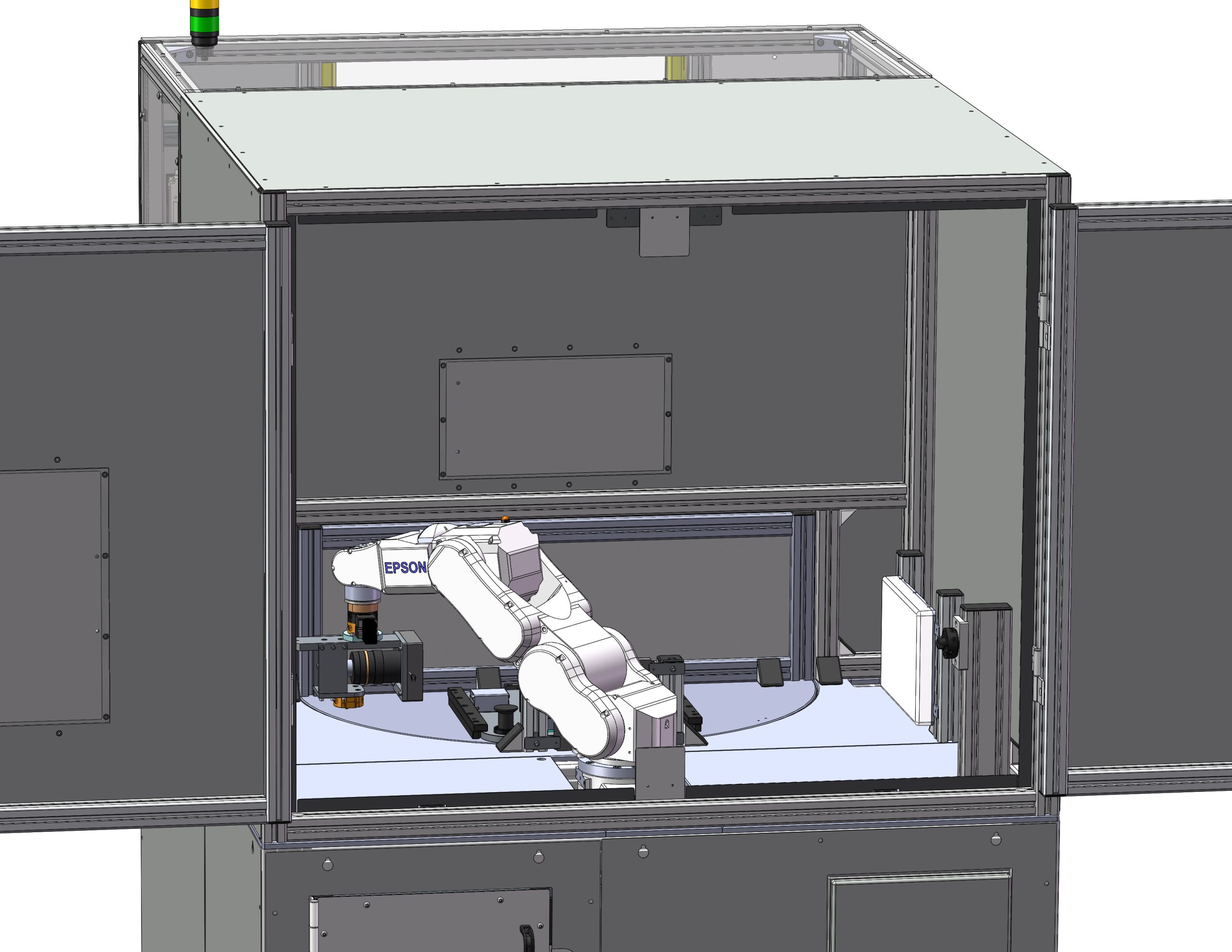

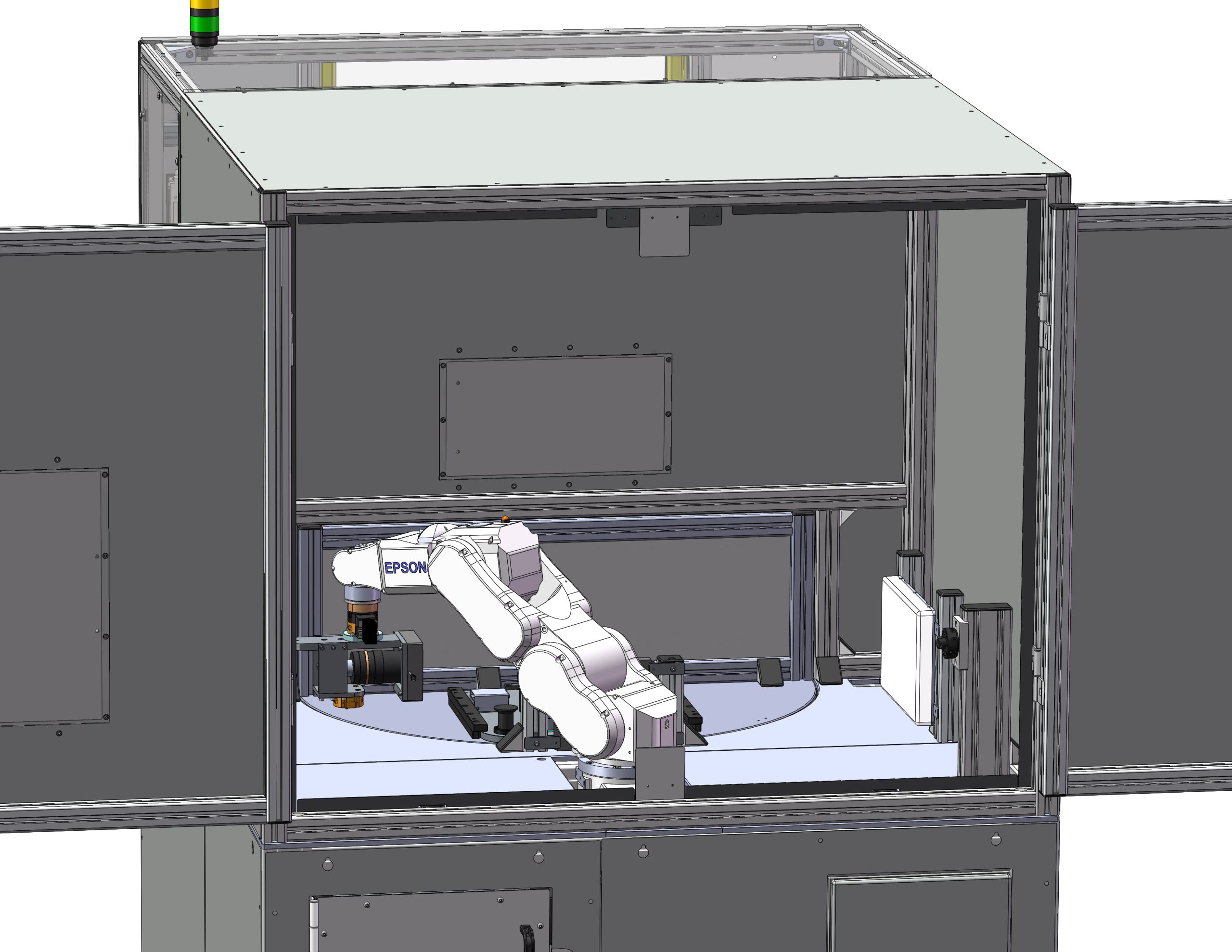

– With a 6-axis industrial robot, the product can be tested from different sides and angles, so it is also suitable for checking connecting dimensions and used as an EOL tester as well

– Different built-in lights for different inspections

– Shorter cycle time can be achieved with rotary table solution

– Easily interchangeable nests; with the help of these nests, the machine is suitable for testing several different products with quick changeover

Result:

The result is an universal robotic device which can monitor a wide range of components using different cameras and illuminations.

Due to the interchangeable nests, the manufacturing of a new product can be the fraction of the investment cost.

Verifiable parameters:

– Presence and position of connecting pins

– Presence and conformity of labels and captions

– Check connecting dimensions

– Different color, shape, presence and size controls

– Paste presence and continuity

– Quality criteria (burrs, scratches)