Owner: Pankl Racing Systems AG

Field of expertise:

Methods:

Application area:

Industry:

Pankl Racing Systems AG is a leading supplier of engine and drivetrain systems and components for all segments of motor sports, as well as for the aerospace and high-performance industry. The company deals with development and production of engine and drivetrain components. The components can be made from a wide range of materials, especially high-strength steel and titanium alloys. One of various methods of manufacturing of the components includes additive manufacturing (AM).

Challenges

The product development team at Prankl Racing System uses AM for rapid design and production of engine and drivetrain components for motorbikes and racecars. Because of this, they need to consider a new set of material options, manufacturing constraints, structural and thermal impacts of the production process such as thermal stresses and warping, as well as optimize the design for AM process. Some of these challenges need to be managed by using support structures which would conduct heat away from the part which is being built. The chosen materials need to be appropriate for such production process, as well as for operating conditions of the components.

Technologies used

- Ansys Workbench Additive

- Ansys SpaceClaim

- Ansys Granta AM Selector

- Ansys HPC

Engineering solution

The development team at Pankl Racing was able to make decisions among materials and printing costs and other factors such as structural and thermal performance. Ansys SpaceClaim helps them with design exploration and creation of complex shapes with unique design features appropriate both for autoracing and conditions of metal 3D printing. With Ansys Granta Selector, the team is able to rapidly specify the appropriate powder formula based on performance parameters and material availability, as well as different material/heat treatment combinations.

Benefits

Ansys Granta Selector enables the team to choose an appropriate powder formula based on various parameters. Ansys SpaceClaim ensures creation of unique designs and the additive package helps define appropriate parameters for AM process of the designed components.

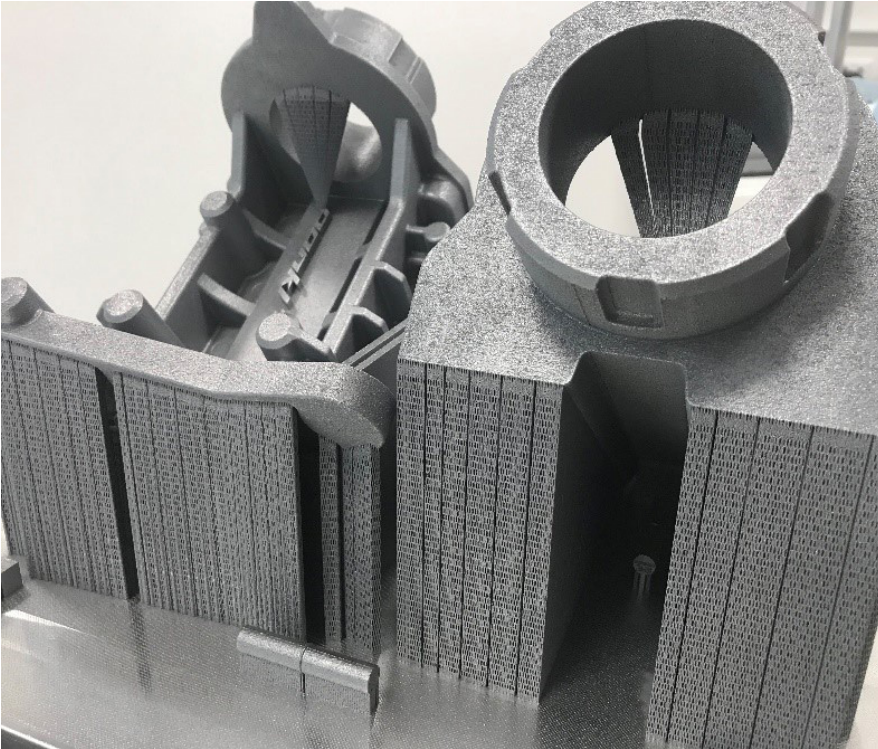

Supports during metal 3D printing process

Drivetrain component produced

by additive manufacturing method

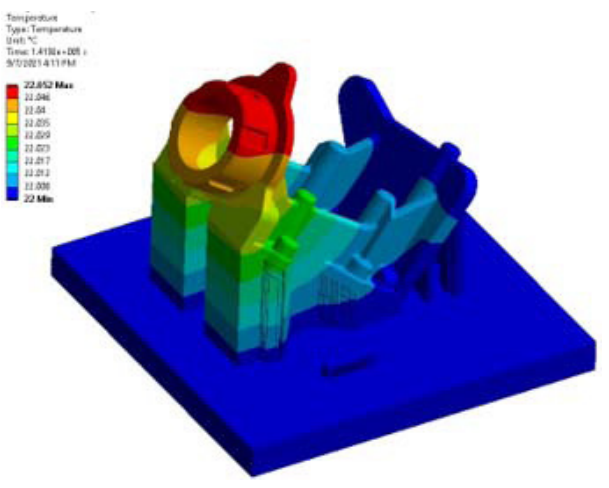

Temperature distribution during AM process