Field of expertise:

Methods:

Application area:

Industry:

The process has two steps:

– First we melt the river head with hot air (the air temperature and the mass flow are measured)

– Second we depress the rivet head with a heated riveter.

The advantages of the process:

- Strong shape lock binding – the melt will fill out more than 90% of the hole

- There won’t be cracking on the rivet material even with filled plastic

- The rivet won’t become sensitive for vibration

- Ecstatically smooth rivet head can be made

We ensure the stability of the process with

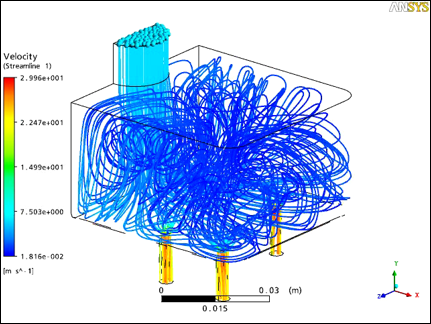

- CFD flow simulation for the air nozzles, and heat simulation for the hot press heads

- Controlled air mass and temperature

- Heat sensors for the PBC surfaces against overheating