Field of expertise:

Methods:

Application area:

Industry:

In injection molding, the application of proper gating and cooling is crucial for the quality of the final product, manufacturing efficiency, and cost. Proper gating ensures that the molten plastic flows evenly into all parts of the mold, avoiding air traps and cold welds. Also, an optimal cooling system generates even temperature distribution, reducing shrinkage-related defects and improving surface quality, while also resulting in faster solidification, which decreases cycle time and increases production speed.

Challenge

In order to find the optimal design, we need to examine:

- the efficiency of different cooling designs;

- the impact of gate position, type, and number;

- the effect of changing injection parameters;

- the interaction between cooling and gating arrangements.

Methods, softwares used

- Moldex3D

- Finite Element Method (FEM)

- Design of Experiments (DOE)

Engineering solution

The Expert module offered by Moldex3D provides the opportunity to use design of experiments (DOE) to investigate not only the effects of injection molding parameters but also the impact of geometric modifications, such as cooling and gating arrangements, using meshes specified as input for the study. In this example, we are searching for the most ideal option among single-gate and double-gate concepts, as well as straight-section and conformal cooling designs.

In addition to different geometric parameters, we also consider the consequences of varying the melt temperature. We examine 3 different temperatures based on the suggestions by the Moldex3D material database. In addition to these, we also have the opportunity to examine other parameters, such as different materials, packing pressure settings, cooling times, and so on.

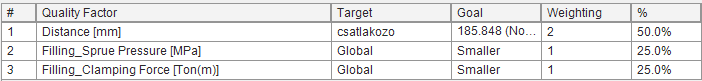

To find the most suitable concept for us, we can specify conditions and assign weights to indicate the importance of each condition. In this example, we have considered connector size, maximum sprue pressure, and maximum clamping force. But there is also the option to include considerations for flatness, shear rate, volumetric shrinkage distribution, and other outputs.

Benefits

The Moldex3D Expert module offers the following benefits to users:

- It creates and runs simulations by numerous parameter variations.

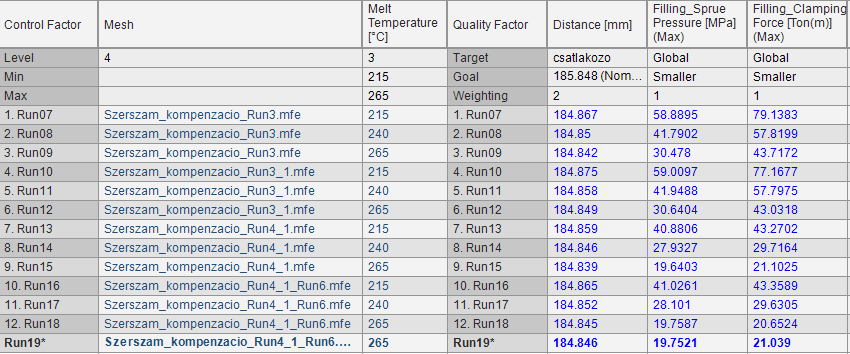

- It determines the best concept based on the defined quality factors. In this case the best option is to use 265°C for melt temperature with conformal cooling and two-gate design.

- It can also handle meshes as input parameters, taking geometric modifications into account.

- It creates graphs to evaluate the impact of parameters on results, showing how much each parameter has influenced the outcome.

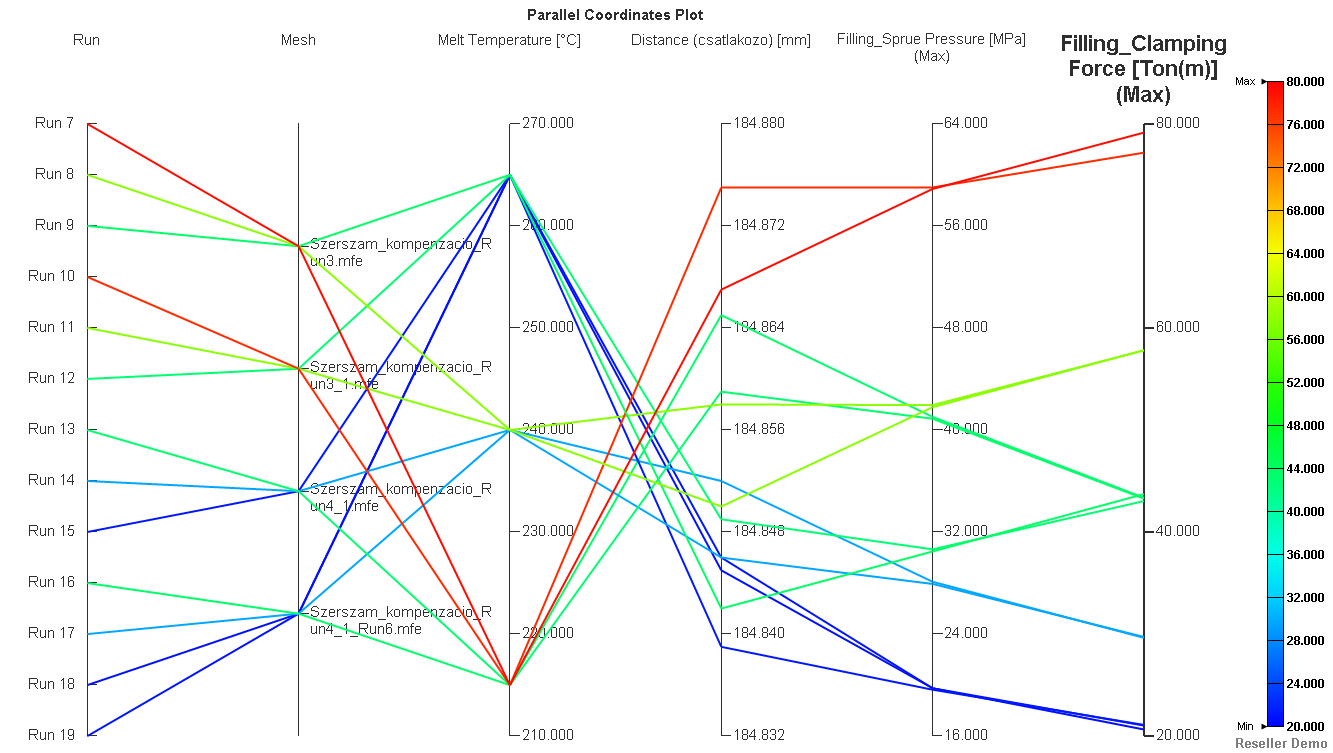

- It produces graphs and tables for better clarity and visibility of the results.

Analysed coolant layouts and gate positions

DOE quality factors

Response graph:

effect of the different gating positions, cooling systems and injection temperature

Results summary table

Diagram: parallel coordinate plot