Field of expertise:

Methods:

Application area:

Industry:

In the development of hand tools, the droptests mean basic requirements. The use of explicit simulations in the development phase is essential.

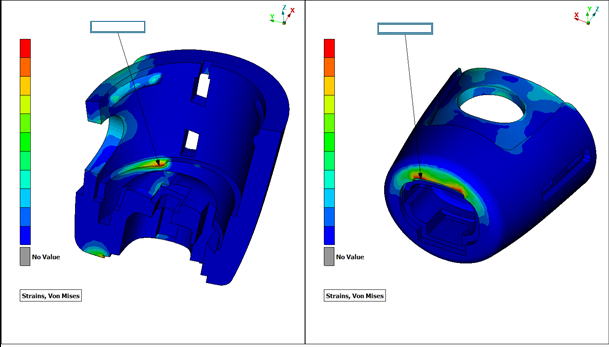

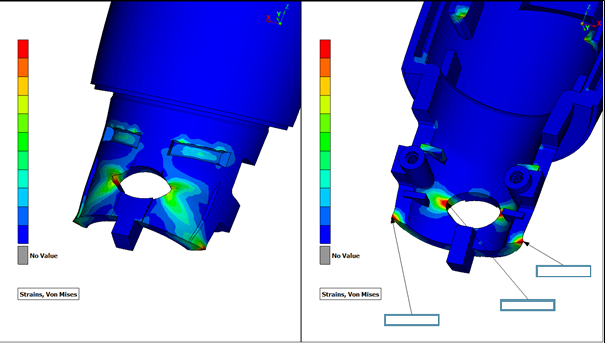

The droptest of the drill was simulated with different initial heights and angels of attack. Ansys Ls-Dyna was used as finite element solver. The evaluation of failure was performed using different failure criteria. Development suggestions were made and the initial design was improved successfully.

With the help of the simulations, proper material selection could be made, and an optimal geometry could be defined, so that the stiffness and strength of the parts can fit the requirements.