Field of expertise:

Application area:

Industry:

In order to develop a more efficient heat exchanger for a high-end refrigerator, engineers needed to realistically model the flow and deposition of dirt, dust, hair and cotton fibers throughout the component.

Combining Ansys Rocky DEM with CFD provides real insight on understanding a specific speck of dust on a specific surface within a certain geometry. Our task is to create a design around that reality. That means developing a refrigerator heat exchanger that is robust to dust accumulation.

This issue is exacerbated by dirt accumulation on the condenser (heat exchanger), which can impact appliance performance.

Method

One of the first steps in heat exchanger investigation was how to define and represent relevant airborne materials. These are collectively referred to as foulant. At the time, the research team had been using Computational Fluid Dynamics (CFD) to model simple spherical dust specks within an air stream. But they needed to include non-spherical dirt particles, high aspect–ratio hair, and flexible fibers like cotton. These require DEM method like Ansys Rocky. Rocky offers accurate particle physics to predict behavior in a reasonable solve time. Initially CFD model was used for the heat exchanger’s fluid flow, which affects overall efficiency. DEM would yield information on particle deposition, fluid forces acting on particles, such as drag, and adhesion forces, ultimately assessing of how the heat exchanger design affects particle behavior.

Experimental evaluation of dirt accumulation on condensers is time-consuming and expensive. Consequently, we need to couplie computational fluid dynamics (CFD) and discrete element modeling (DEM) to quickly gain insight on the mechanisms behind dirt accumulation — in an effort to design a more robust heat exchanger.

Results

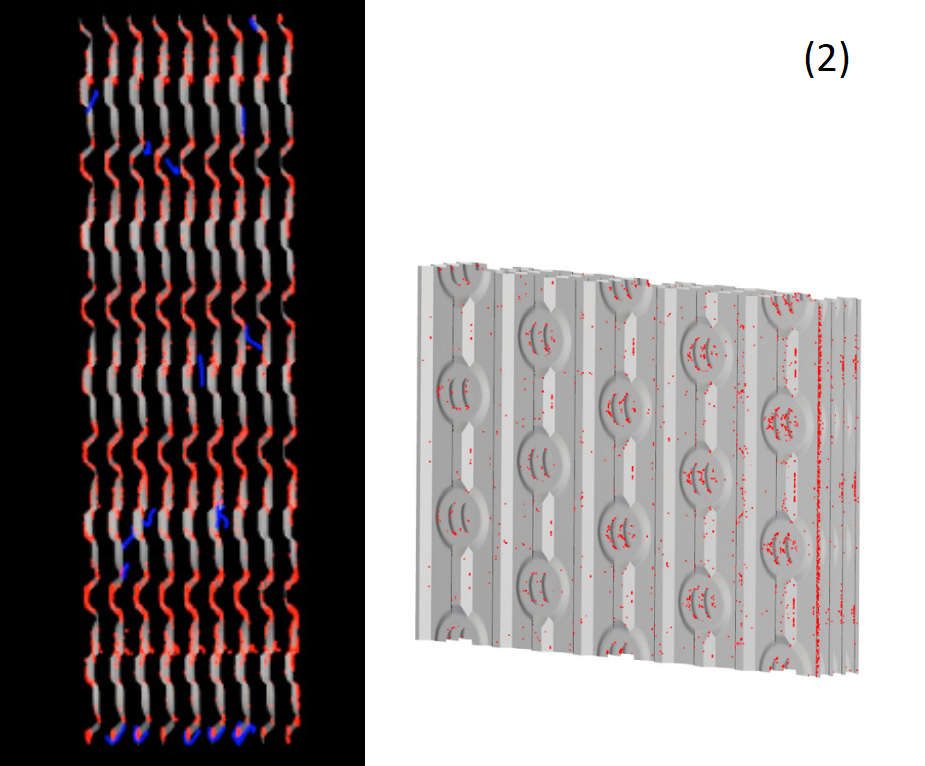

Rocky DEM simulation results show deposition pattern. In Figure 2. hair and cotton fibers (shown in blue) accumulate on fins’ leading edges. Dust (shown in red) amasses in low-velocity zones.

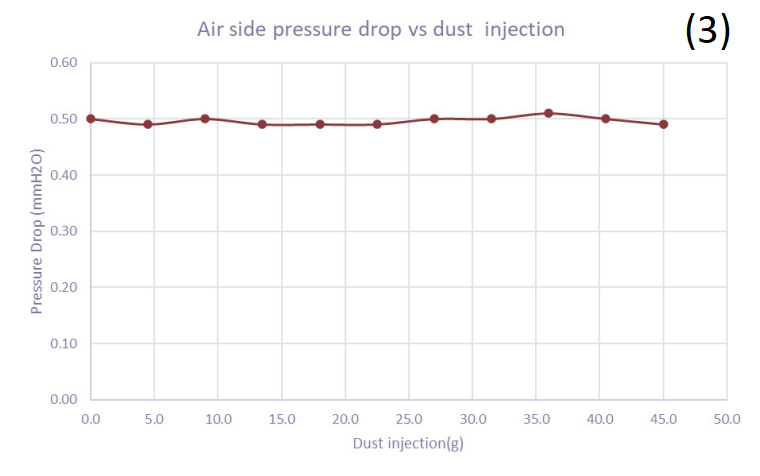

Experience shows that in average cases, one-way coupling is enough. In a different situation, a greasy or oily heat exchanger might exhibit greater particle adhesion, requiring two-way coupling. (3)