Field of expertise:

Methods:

Application area:

Industry:

Area:

Design of an automatic manufacturing cell for automotive components production. The manufacturing cell is suitable for assembling Press-Fit connectors, where also the process parameters can be set. (Stroke and force control.) In this case, the task is the fixation of a 38-pin connector to a printed-circuit.

Solution:

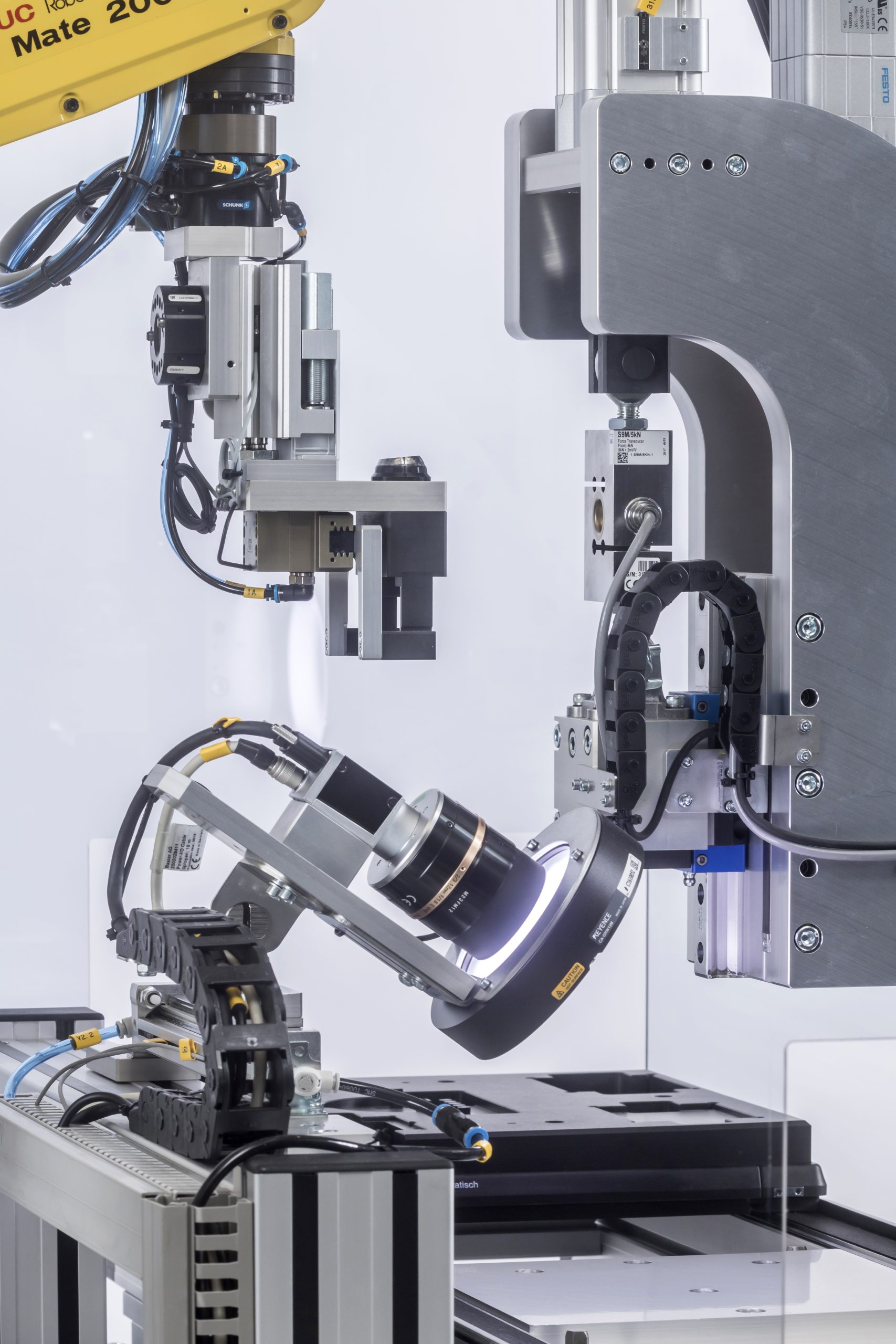

– Connector manipulation with 6-axis industrial robot arm

– Check the connector pins and the PCB mounting holes with an industrial camera, then make the necessary corrections of the robot positions. This makes the system suitable for quality control of connectors and significantly reduces the number of assembly failures.

– Closed-force press unit with stroke or force control during the installation

– A stroke-force diagram is made about the pressing process, which is associated to the product and in each case, it is saved based on an identification number. Based on sample production, the ideal stroke-force curve and reasonable deviations can be determined.

– Preliminary tests are already prepared in the design phase. To test the Press-Fit technology, we also have a tensile and fatigue test in our measuring room. For pre-testing of the camera system, different types of industrial cameras, lenses, filters and illuminations are available.

– During or after the assembly steps, we do additional vision test to check and the quality of each step.

Result:

As per customer requirements, it is a fully automatic manufacturing cell which is:

– Suitable for completing the required technologies (Press-Fit assembly, robotic part movement, camera inspections at several points in the process)

– Flexibly adjustable (setting of pressing parameters, application of stroke or force control, control of stroke-force curve, optimization of robot movements)

– Significantly reduces the number of assembly scraps and ensures the shortest cycle time possible for the process